Building Better Batteries for Cars and Spacecraft

(PhysOrg.com) -- NASA and NREL combine experience and experiments to make safer more reliable batteries for outer space and Interstates.

The NASA engineer responsible for the batteries needed for spacewalks now is working at the Department of Energy's National Renewable Energy Laboratory to help design safer lithium-ion battery packs for sky walkers and automobile drivers alike.

"We at NASA share the same challenges that DOE and NREL have in developing batteries for cars," said Eric Darcy, the battery group leader at the National Aeronautics and Space Administration's Johnson Space Center.

Whether it's "manned space travel or manned automobiles," the hurdles are the same, Darcy said. "Designing a safe, very large and lightweight battery pack for the confined space of manned vehicles is challenging."

In the future, battery-powered automobiles are expected to grab a big share of the market away from gasoline-fueled vehicles.

Lithium ion batteries are the technology of choice because of their high energy and power densities, Ahmad Pesaran, Energy Storage Group Leader at NREL, said. But the batteries must be able to withstand abuses that could lead to thermal runaway and potentially fire.

Thermal runaway can happen when an increase in temperature changes conditions in a way that leads to a further increase in temperature, a kind of feedback that can lead to catastrophe. The increase in temperature leads to an increase in the reaction rate, which leads to further increases in temperature. The disastrous release of methyl isocyanate gas from a Union Carbide plant in Bhopal, India, in 1984, was precipitated by a thermal runaway.

Researchers in NREL's Energy Storage Group are modeling and testing how well the risk of catastrophic thermal runaway can be mitigated in lithium-ion cell/battery designs. "We're privileged to have Eric working with us for nine months," Pesaran said.

NREL researchers expect the partnership to help them design next-generation battery packs for cars. Darcy's contributions are helping NREL's integrated network model to analyze the qualities of multi-cell battery pack systems and observe their responses to stress, NREL engineer Gi-Heon Kim said. "These kinds of model tools are crucial for car industries to properly perform thermal and safety assessment of their battery pack designs."

Inducing Shorts on Demand

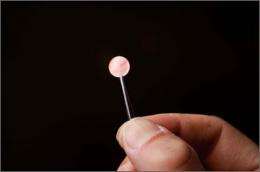

NREL and NASA engineers have invented specially designed small "coins" made of primarily aluminum and copper, that when implanted into lithium ion cells will induce an internal short circuit on demand. The ability to accurately replicate internal shorts in battery cells is crucial to finding out how hot a battery can get when one of its cells fails because of a rare manufacturing defect. Those defects happen only about one time in 1 million in the field, but because of their catastrophic consequences, NASA and NREL need to lengthen those odds if lithium-ion batteries are to become the workhorses of space walks and automobile transportation.

Darcy brings 23 years of experience in putting together batteries for manned spacecraft. With the retirement of the Space Shuttle Program, and the uncertainty of when a replacement will be available, NASA needs a new-generation, longer life spacesuit battery pack that will support dozens of walks based from the Space Station.

"Eric brings the perspective and broad experience base of the aerospace industry," says NREL researcher Kandler Smith. The aerospace industry doesn't share the same cost constraints of the automotive industry, "but the processes employed for battery risk assessment and design for reliability are directly applicable."

NREL researchers have characterized the conditions under which an internal short circuit in a spacesuit battery can lead to a thermal runaway, which can cause a catastrophic explosion.

"Knowing the vulnerabilities of that battery is useful to find a way to mitigate the risks," Smith said.

Safer Spacesuit Battery under Development

NASA has been developing a new spacesuit battery for three years, preparing for the time when the current short wet life battery packs of the shuttle-to-space-station era would require replacement.

"We now need at minimum, a five-year battery, and with that comes a whole new chemistry, lithium-ion," Darcy said.

"That carries with it the risk of it rupture and fire," Darcy added. "That's why we've teamed with NREL to characterize the small range of conditions under which this battery can go into thermal runaway." The Interagency Government Agreement between NASA and NREL was signed in 2008.

The battery under study contains 80 laptop-sized lithium-ion cells, weighs about 15 pounds, and is about 11 inches long, four inches wide and five inches deep. Laptop batteries can last three years if they're treated kindly, albeit they usually aren't, since most of the time they are kept fully charged and operate at high temperatures inside the cramped internal space of a laptop.

The new spacesuit battery will rest inside the backpack on the spacesuit, which packs a lot of thermal insulation, preventing it from getting very cold or very hot. So, even though it will be in the forbidding climes of outer space, it will experience less stress than a battery constantly being charged and discharged on planet Earth.

Designed to Last for 50 Space Walks

The battery is designed to endure some 50 multi-hour space walks over its five year life, although typically it would be taken out for about half that many walks.

The lithium-ion battery will power all the life-support systems in the space suit, powering the fans that circulate the air, powering the heat exchanger, the pumps that circulate water through the suit.

Suits will accompany the astronauts on the transfer to the space station, while others will be parked permanently at the station, for the times when the astronauts have to take a walk when there's no shuttle spacecraft around.

NASA is planning more lower-orbit satellites to observe the Earth for climate-change data. The space station is going to be crucial for those close-Earth observations, and that means safe, long-lasting spacesuit batteries will be crucial, too.

Auditing Performance of Lithium-ion Batteries

NASA needs to learn all it can about lithium-ion batteries because the nickel-hydrogen batteries now in use will expire in 2017.

"We're performing audits on the cell production lines" of the lithium-ion batteries, Darcy said.

Tiny latent defects imbedded in cells can be missed if testing isn't done under the strictest conditions. Those defects could cause an internal short circuit and a catastrophic event.

Internal short circuits are rare, but not unheard of. "You hear about these one-in-a-million recalls, when a laptop or a cell phone's battery defect causes it to go into flames," Darcy said.

Early this month, Darcy and Smith audited a lithium-ion manufacturing process. "They had some good processes and some weaknesses," Darcy said. "We made a long list of all those actions they ought to consider correcting to produce a better, safer product."

The lessons learned at the audits can be used by NREL to conduct similar audits on automobile battery manufacturers, Darcy said.

"It's important that they do so, because if an incident occurred on a car battery, it would be a cancer to everyone who uses lithium-ion batteries," Darcy said. "Is mine going to have that same effect?

"They need to know why or why not. What measures can they take to minimize the risk of some kind of internal short inside the cell that can make it blow up?"

Provided by National Renewable Energy Laboratory