Nanotubes that Heal: Engineering Better Orthopedic Implants

(PhysOrg.com) -- Titanium and its alloys have a leg up on all other materials used to make the orthopedic implants used by surgeons to repair damaged bones and joints. They are light, super-strong, and virtually inert inside the body. But whether the implants are destined for your knee, your hip, your spine or your jaw, the silvery metal has one big drawback.

“Titanium has a mirror surface,” says Tolou Shokufar, a PhD candidate in mechanical engineering-engineering mechanics. Cells don’t adhere to it very well, so implants are often roughened up before they are placed in the body.

A good way to roughen titanium is to etch nanotubes into it, since they provide a superb surface for bone cells to grasp onto as part of the healing process. But etching nanotubes in the titanium alloy preferred by surgeons is not cheap. Conventional techniques require platinum, which costs over $1,700 an ounce.

Through her PhD work with Professor Craig Friedrich, director of the Multi-scale Technologies Institute, Shokufar has developed a less expensive way to etch nanotubes into the titanium alloy. In a weak solution of ammonium fluoride, she immerses two rods, one of the alloy, another of copper, and hooks them up to a power source. An electrical current flows into the copper, through the solution and out the titanium.

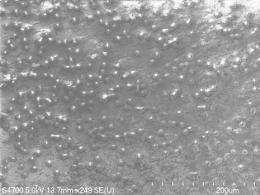

“It corrodes the titanium dioxide layer on the titanium in the form of a tube,” Shokufar says, making nanotubes about seven microns long and a hundred nanometers in diameter. Growing the ideal tube takes about two hours.

Then she applies heat and pressure to the titanium alloy, annealing the nanotubes to give them a hydrophilic, crystalline structure. The surface not only attracts water, tests show it provides a friendly place for cells to grow. Shokufar has conducted experiments with fibroblasts—cells that make scar tissue—showing they grow faster on a layer of her titanium dioxide nanotubes than on the unaltered surface of the titanium alloy. Next, she aims to do a similar experiment with bone-growing osteoblasts.

Because the nanotubes are chemically identical to the titanium alloy, Shokufar expects that her innovation could be approved for medical use with relative ease. It may also have a wide variety of other applications, ranging from drug delivery to solar cells to hydrogen generation.

Her technique seems simple, but it didn’t start out that way. “It took a lot of time to figure out,” she says. “I’d spend days and days under the SEM, and when I went to sleep, I saw nanotubes inside my eyelids.”

It’s been worth it to see the perfect sheets of nanotubes grow under her care, however. “I really like them,” she says. “They are like my babies.”

Provided by Michigan Technological University