The goal of robot hockey: to become better engineers (w/ Video)

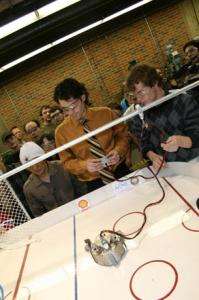

(PhysOrg.com) -- It may be a long time before we see robots shooting pucks and making saves in professional hockey, but second-year mechanical engineering students at the University of Alberta put some pretty impressive players to the test as part of a creative design course.

Called Hockey Shoot Out, the assignment was the brainchild of Pierre Mertiny, who teaches the Design 260 course. Working in teams of four, students had to design and build remote-control "robots" capable of scoring goals and stopping shots on a scale hockey rink.

Each team was given the same set of materials and access to the Department of Mechanical Engineering's shop and staff of machinist technicians. And while the point of the competition was to put pucks in the net, Mertiny says the goal of the assignment went further than that.

"The real goal is for them to become better engineers," Mertiny said. "It seems like the purpose is the machines, but it is the journey. They need to show good teamwork and use all of the tools available to them in the shop."

And while the students were clearly enjoying themselves in the competition-the event always draws a huge crowd of students and news media-the real fun is in the learning.

"It's a completely different kind of learning," said student Angela Climenhaga. "You could spend an hour trying to solve a problem and it still wouldn't work."

Climenhaga estimated that she put in close to 10 hours of work on the project each week.

Teammate John Peters said one of the most important lessons in the assignment was teamwork.

"When you're working on a team, everyone has to be trusted to finish what they were assigned. It isn't the same as when you're doing homework together and everyone is working on the same question."

"You learn how to resolve differences of opinion, and to stick to what is in the best interest of the team and the project," added teammate Mohammad Marmash.

For student Drew Hogg, the assignment presented an important learning opportunity.

"When I found out we could use these tools I was just drooling," he said, adding that his team used both the shop's water-jet cutter to custom manufacture parts, and its rapid prototype machine, which takes computer-designed parts and machines them from plastic using a laser light.

"Doing this hands-on work is really important," said Hogg. "It's one thing to read about things and look at pictures in a textbook but hands-on really adds another dimension."

Provided by University of Alberta (news : web)