The Shrinky Dink solution

Toys don't usually inspire high-tech innovation, but Michelle Khine's childhood favorite did just that.

The UC Irvine assistant professor in biomedical engineering drew upon the hours she spent playing with Shrinky Dinks — thin plastic sheets that can be colored with paint or ink and then shrunk with heat — to solve a problem in her research on how chemical cues affect cell activity.

The work earned Khine a spot on Technology Review's 2009 TR35, an annual list of 35 innovators under 35 in business and technology worldwide. Technology Review is published by the Massachusetts Institute of Technology.

"They say desperation is the mother of all invention, but I also have to credit my actual mother," Khine says. "When I was 6 years old, she introduced me to what became my lifelong No. 1 toy: Shrinky Dinks."

After earning her doctorate, Khine joined the founding faculty at UC Merced in 2006. The fledgling campus didn't have the sophisticated lab equipment of her grad school days, so Khine had to find a way to create fluid channels thinner than a human hair on the biochips she employed in her research. She wondered if she could pattern the pathways on a Shrinky Dink sheet with her desktop laser printer and then miniaturize them in a toaster oven.

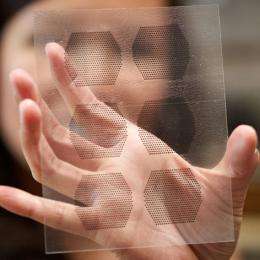

It worked. As the plastic shrank, the ink particles on its surface clumped together and formed tiny ridges. After removing it from the oven, Khine applied a flexible polymer called PDMS to the cooling sheet. The ink ridges created channels in the PDMS, and when Khine peeled the polymer off the Shrinky Dink mold, she had a completed microfluidic device.

The use of PDMS to construct miniscule features on wafers is called soft lithography, and it typically involves several days of turnaround time and considerable infrastructure, operating expenses (such as for a clean room) and equipment.

With the Shrinky Dink method, Khine says, researchers can easily and cheaply design and develop custom microfluidic chips within minutes. "And all they'll need is a laser printer and a toaster oven," she says.

This simplified fabrication process could revolutionize the way engineers conduct experiments and manufacture products, Khine believes, and could be used in stem cell research, to create cardiac patches for heart attack sufferers and to significantly improve the detection sensitivity of bioassays, which are utilized in pharmaceutical development and point-of-care diagnostics.

In fact, Khine's toy-inspired innovation led to the first start-up company at UC Merced, Shrink Nanotechnologies Inc., exclusive licensee of her patent-pending advances.

Khine continues to use Shrinky Dink-style fabrication at UCI, and she encourages other young engineers to approach their research creatively.

"My advice?" she says. "Be true to your inner child. Don't work - play! If you love what you do, you'll do great things."

Provided by University of California, Irvine