Chemists offer new hydrogen purification method

(PhysOrg.com) -- President Barack Obama's pursuit of energy independence promises to accelerate research and development for alternative energy sources -- solar, wind and geothermal power, biofuels, hydrogen and biomass, to name a few.

For the hydrogen economy, one of the roadblocks to success is the hydrogen itself. Hydrogen needs to be purified before it can be used as fuel for fuel cells, but current methods are not very clean or efficient.

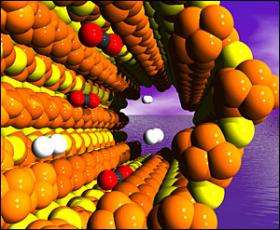

Northwestern University chemist Mercouri G. Kanatzidis, together with postdoctoral research associate Gerasimos S. Armatas, has developed a class of new porous materials, structured like honeycomb, that is very effective at separating hydrogen from complex gas mixtures. The materials exhibit the best selectivity in separating hydrogen from carbon dioxide and methane, to the best of the researchers' knowledge.

The results, which offer a new way to separate gases not available before, will be published online Feb. 15 by the journal Nature Materials. The materials are a new family of germanium-rich chalcogenides.

"A more selective process means fewer cycles to produce pure hydrogen, increasing efficiency," said Kanatzidis, Charles E. and Emma H. Morrison Professor of Chemistry in the Weinberg College of Arts and Sciences and the paper's senior author. "Our materials could be used very effectively as membranes for gas separation. We have demonstrated their superior performance."

Current methods of producing hydrogen first yield hydrogen combined with carbon dioxide or hydrogen combined with carbon dioxide and methane. The technology currently used for the next step -- removing the hydrogen from such mixtures -- separates the gas molecules based on their size, which is difficult to do.

Kanatzidis and Armatas offer a better solution. Their new materials do not rely on size for separation but instead on polarization -- the interaction of the gas molecules with the walls of the material as the molecules move through the membrane. This is the basis of the new separation method.

Tests of one form of the family of materials -- this one composed of the heavy elements germanium, lead and tellurium -- showed it to be approximately four times more selective at separating hydrogen from carbon dioxide than conventional methods, which are made of lighter elements, such as silicon, oxygen and carbon.

"We are taking advantage of what we call 'soft' atoms, which form the membrane's walls," said Kanatzidis. "These soft-wall atoms like to interact with other soft molecules passing by, slowing them down as they pass through the membrane. Hydrogen, the smallest element, is a 'hard' molecule. It zips right through while softer molecules, like carbon dioxide and methane take more time."

Kanatzidis and Armatas tested their membrane on a complex mixture of four gases. Hydrogen passed through first, followed in order by carbon monoxide, methane and carbon dioxide. As the smallest and hardest molecule, hydrogen interacted the least with the membrane, and carbon dioxide, as the softest molecule of the four, interacted the most.

Another advantage is that the process takes place at what Kanatzidis calls a "convenient temperature range" -- between zero degrees Celsius and room temperature.

Small-molecule diffusion through porous materials is a nanoscopic phenomenon, say the researchers. All the pores in the hexagonal honeycomb structure are ordered and parallel, with each hole approximately two to three nanometers wide. The gas molecules are all at least half a nanometer wide.

The paper is titled "Mesoporous Germanium-Rich Chalcogenido Frameworks with Highly Polarizable Surfaces and Relevance to Gas Separation."

Source: Northwestern University