New polymer coatings prevent corrosion, even when scratched

Imagine tiny cracks in your patio table healing by themselves, or the first small scratch on your new car disappearing by itself. This and more may be possible with self-healing coatings being developed at the University of Illinois.

The new coatings are designed to better protect materials from the effects of environmental exposure. Applications range from automotive paints and marine varnishes to the thick, rubbery coatings on patio furniture and park benches.

"Starting from our earlier work on self-healing materials at the U. of I., we have now created self-healing coatings that automatically repair themselves and prevent corrosion of the underlying substrate," said Paul Braun, a University Scholar and professor of materials science and engineering. Braun is corresponding author of a paper accepted for publication in the journal Advanced Materials.

To make self-repairing coatings, the researchers first encapsulate a catalyst into spheres less than 100 microns in diameter (a micron is 1 millionth of a meter). They also encapsulate a healing agent into similarly sized microcapsules. The microcapsules are then dispersed within the desired coating material and applied to the substrate.

"By encapsulating both the catalyst and the healing agent, we have created a dual capsule system that can be added to virtually any liquid coating material," said Braun, who also is affiliated with the university's Beckman Institute, Frederick Seitz Materials Research Laboratory, department of chemistry, and Micro and Nanotechnology Laboratory.

When the coating is scratched, some of the capsules break open, spilling their contents into the damaged region. The catalyst and healing agent react, repairing the damage within minutes or hours, depending upon environmental conditions.

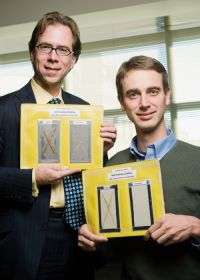

The performance of the self-healing coating system was evaluated through corrosion testing of damaged and healed coated steel samples compared to control samples that contained no healing agents in the coating. Reproducible damage was induced by scratching through the 100-micron-thick polymer coating and into the steel substrate using a razor blade. The samples were then immersed in a salt solution and compared over time.

The control samples corroded within 24 hours and exhibited extensive rust formation, most prevalently within the groove of the scratched regions, but also extending across the substrate surface, the researchers report. In dramatic contrast, the self-healing samples showed no visual evidence of corrosion even after 120 hours of exposure.

"Our dual capsule healing system offers a general approach to self-healing coatings that operates across a broad spectrum of coating chemistries," Braun said. "The microcapsule motif also provides a delivery mechanism for corrosion inhibitors, antimicrobial agents, and other functional chemicals."

Source: University of Illinois at Urbana-Champaign