Nanotech clay armour creates fire resistant hard wearing latex emulsion paints

Researchers at the University of Warwick's Department of Chemistry have found a way of replacing the soap used to stabilize latex emulsion paints with nanotech sized clay armour that can create a much more hard wearing and fire resistant paint.

To date latex emulsion paints have relied on the addition of soaps or similar materials to overcome the polymer parts of the paint's aversion to water, stabilize the paint, and make it work.

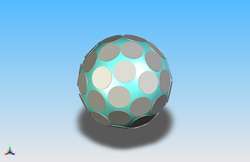

The University of Warwick chemistry researchers led by Dr Stefan Bon have found a simple way to individually coat the polymer particles used in such paints with a series of nanosized Laponite clay discs. The discs effectively create an armoured layer on the individual polymer latex particles in the paint. The clay discs are 1 nanometre thick by 25 nanometres in diameter.

The Lapointe clay discs can be applied using current industrial paint manufacture equipment. They not only provides an alternative to soap but can also be used to make the paint much more hard wearing and fire resistant.

The process devised by the Warwick team can be used to create highly sensitive materials for sensors. The researchers can take closely packed sample of the armoured polymers and heat it to burn away the polymer cores of the armoured particles leaving just a network of nanotech sized connected hollow spheres. This gives a very large useful surface area in a very small space which is an ideal material to use to create compact but highly sensitive sensors.

Their research is in a paper enitled "Pickering Miniemulsion Polymerization Using Laponite Clay as a Stabilizer" by Stefan A. F. Bon and Patrick J. Colver and is published as the cover article in Langmuir. The ACS Journal of Surfaces and Colloids Vol. 23, Issue 16 July 31.

Source: University of Warwick