February 2, 2021 report

A new way to make wood transparent, stronger and lighter than glass

A team of researchers at the University of Maryland, has found a new way to make wood transparent. In their paper published in the journal Science Advances, the group describes their process and why they believe it is better than the old process.

Transparent wood is an idea that scientists have been working on for some time. Home builders see it as a new option for houses because wood is stronger than glass—it would not shatter if struck by an errant baseball, for example. But despite much effort, transparent wood has not made it into commercial use—mostly because of the way it is made.

The conventional method for making wood transparent involves using chemicals to remove the lignin—a process that takes a long time, produces a lot of liquid waste and results in weaker wood. In this new effort, the researchers have found a way to make wood transparent without having to remove the lignin.

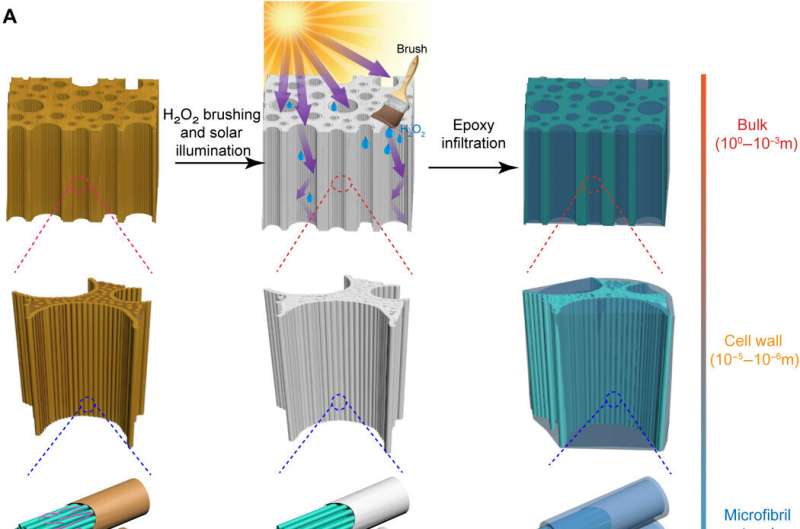

The process involved changing the lignin rather than removing it. The researchers removed lignin molecules that are involved in producing wood color. First, they applied hydrogen peroxide to the wood surface and then exposed the treated wood to UV light (or natural sunlight). The wood was then soaked in ethanol to further clean it. Next, they filled in the pores with clear epoxy to make the wood smooth.

The wood that resulted was found to be 50 times stronger than transparent wood made the conventional way—it also allowed 90% of light to pass through. The researchers also found it to be both stronger and lighter than glass—and it provided better insulation. The researchers suggest that it could be used for both windows and roofs. They note that the wood could in theory be used to create an entirely see-through house because it can also be used as a load-bearing material.

The researchers claim wood made using their process is clean and could be easily scaled for use in large buildings. They suggest also that it could be used in other applications, such as touch-sensitive displays for use in harsh environments or inside of cars.

More information: Qinqin Xia et al. Solar-assisted fabrication of large-scale, patternable transparent wood, Science Advances (2021). DOI: 10.1126/sciadv.abd7342

Journal information: Science Advances

© 2021 Science X Network