New 3-D printing technique for biomaterials

A new way of 3-D printing soft materials such as gels and collagens offers a major step forward in the manufacture of artificial medical implants.

Developed by researchers at the University of Birmingham, the technique could be used to print soft biomaterials that could be used to repair defects in the body.

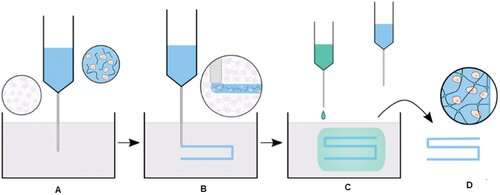

Printing soft materials using additive manufacturing has been a big challenge for scientists because if they are not supported, they sag and lose their shape. The new technique, called Suspended Layer Additive Manufacturing (SLAM), uses a polymer-based hydrogel in which the particles have been manipulated to create a self-healing gel. Liquids or gels can be injected directly into this medium and built up in layers to create a 3-D shape.

The method offers an alternative to existing techniques which use gels that have been minced to form a slurry bath into which the printed material is injected. Called Freeform Reversible Embedding of Suspended Hydrogels (FRESH), these offer many advantages, but frictions within the gel medium can distort the printing.

In a study published in Advanced Functional Materials, a team led by Professor Liam Grover, in the School of Chemical Engineering, show how particles in the gel they have developed can be sheared, or twisted so they separate, but still retain some connection between them. This interaction creates the self-healing effect, enabling the gel to support the printed material so objects can be built with precise detail, without leaking or sagging.

"The hydrogel we have designed has some really intriguing properties that allow us to print soft materials in really fine detail," explains Professor Grover. "It has huge potential for making replacement biomaterials such as heart valves or blood vessels, or for producing biocompatible plugs, that can be used to treat bone and cartilage damage."

SLAM can also be used to create objects made from two or more different materials so could be used to make even more complex soft tissue types, or drug delivery devices, where different rates of release are required.

More information: Jessica J. Senior et al. Fabrication of Complex Hydrogel Structures Using Suspended Layer Additive Manufacturing (SLAM), Advanced Functional Materials (2019). DOI: 10.1002/adfm.201904845

Journal information: Advanced Functional Materials

Provided by University of Birmingham