Putting pressure on 3D-printed structures

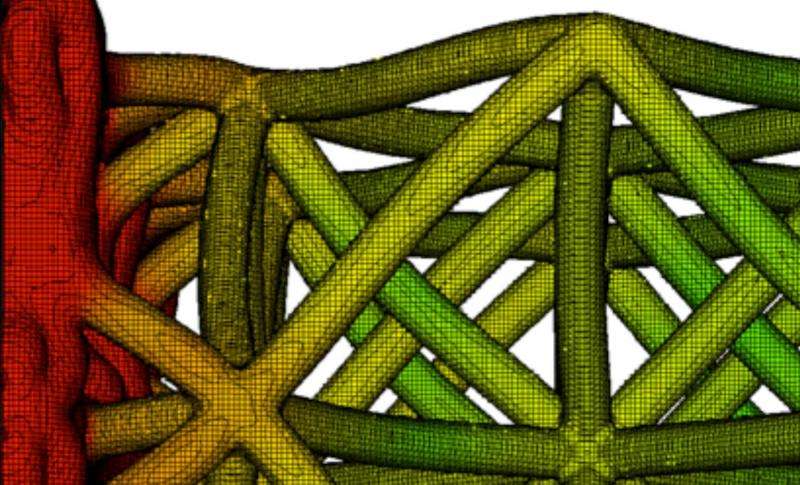

Through a series of dynamic compression experiments on additively manufactured (AM) structured lattices, a Lawrence Livermore National Laboratory team, supported by colleagues at Los Alamos National Laboratory, has found that the assemblies have unique properties not exhibited by disordered cellular materials.

During the experiment, elastic deflection of the structure occurred ahead of the compaction front and in turn the AM lattice materials supported a precursor wave that has not been seen in disordered materials, such as traditional open-cell stochastic foams, which have a comparable density.

This research allows scientists to build accurate models of AM-structured materials under dynamic loading. The study (link is external) is published in the June 20 edition of Scientific Reports.

The physical world is filled with cellular structures—both manmade, like truss bridges, and natural origin, like porous bone tissue. These entities demonstrate a material response optimized through topology rather than composition. Cellular materials have received significant attention over the last several decades for their thermal, electrical and optical properties as well as for their potential as lighter-weight replacements for bulk materials.

Conventional materials design relies on manipulation of chemistry or microstructural length scales, such as grain size distributions. With the advent of AM—often called 3D printing—scientists are able to manipulate the architecture of the cellular material to impart order and periodicity into materials at the mesoscopic scale.

During the recent experiments—conducted at the NNSA-sponsored Dynamic Compression Sector of the Advanced Photon Source at Argonne National Laboratory—the team found that the elastic and compaction behavior exhibits collective response rapidly under impact loading. Time-resolved phase contrast imaging enabled an unprecedented window in real time into the propagation of a stress wave in the lattice structures.

"The basic approach is to be able to use the collective properties of an engineered structure at the micron scale to influence the macromechanical response," said LLNL materials scientist Mukul Kumar, and project lead.

The ability to understand and then organize the structure and composition at the mesoscopic scale allows the custom design of materials by applying structural engineering principles, like truss theory, at the micron length scale. This will open up the possibility of designing and engineering material properties to precisely meet the demands of the intended application.

More information: J. A. Hawreliak et al. Dynamic Behavior of Engineered Lattice Materials, Scientific Reports (2016). DOI: 10.1038/srep28094

Journal information: Scientific Reports

Provided by Lawrence Livermore National Laboratory