System creates on-demand 'nanotube forests,' has potential industry applications

A system that uses a laser and electrical current to precisely position and align carbon nanotubes represents a potential new tool for creating electronic devices out of the tiny fibers.

Because carbon nanotubes have unique thermal and electrical properties, they may have future applications in electronic cooling and as devices in microchips, sensors and circuits. Being able to orient the carbon nanotubes in the same direction and precisely position them could allow these nanostructures to be used in such applications.

However, it is difficult to manipulate something so small that thousands of them would fit within the diameter of a single strand of hair, said Steven T. Wereley, a professor of mechanical engineering at Purdue University.

"One of the things we can do with this technique is assemble carbon nanotubes, put them where we want and make them into complicated structures," he said.

New findings from research led by Purdue doctoral student Avanish Mishra are detailed in a paper that has appeared online March 24 in the journal Microsystems and Nanoengineering, published by the Nature Publishing Group.

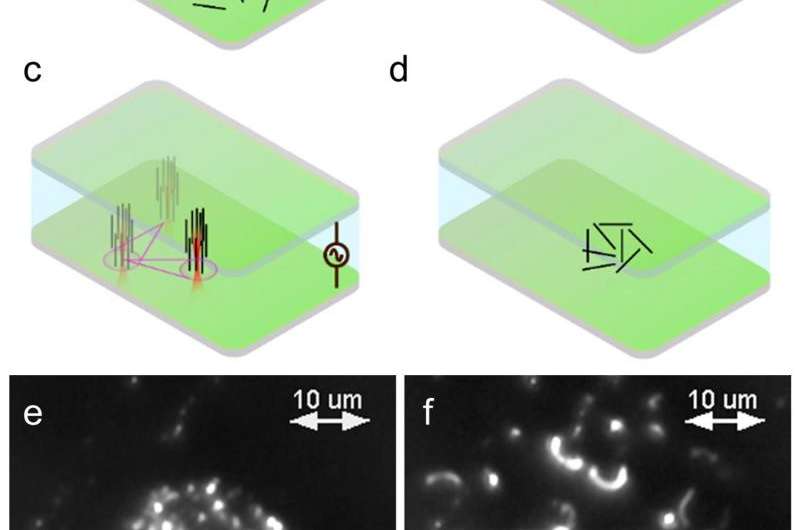

The technique, called rapid electrokinetic patterning (REP), uses two parallel electrodes made of indium tin oxide, a transparent and electrically conductive material. The nanotubes are arranged randomly while suspended in deionized water. Applying an electric field causes them to orient vertically. Then an infrared laser heats the fluid, producing a doughnut-shaped vortex of circulating liquid between the two electrodes. This vortex enables the researchers to move the nanotubes and reposition them.

"When we apply the electric field, they are immediately oriented vertically, and then when we apply the laser, it starts a vortex, that sweeps them into little nanotube forests," Wereley said.

The research paper was authored by Mishra; Purdue graduate student Katherine Clayton; University of Louisville student Vanessa Velasco; Stuart J. Williams, an assistant professor of mechanical engineering at the University of Louisville and director of the Integrated Microfluidic Systems Laboratory; and Wereley. Williams is a former doctoral student at Purdue.

The technique overcomes limitations of other methods for manipulating particles measured on the scale of nanometers, or billionths of a meter. In this study, the procedure was used for multiwalled carbon nanotubes, which are rolled-up ultrathin sheets of carbon called graphene. However, according to the researchers, using this technique other nanoparticles such as nanowires and nanorods can be similarly positioned and fixed in vertical orientation.

More information: Avanish Mishra et al. Dynamic optoelectric trapping and deposition of multiwalled carbon nanotubes, Microsystems & Nanoengineering (2016). DOI: 10.1038/micronano.2016.5

Provided by Purdue University