All-in-one, 3D-printed space antenna

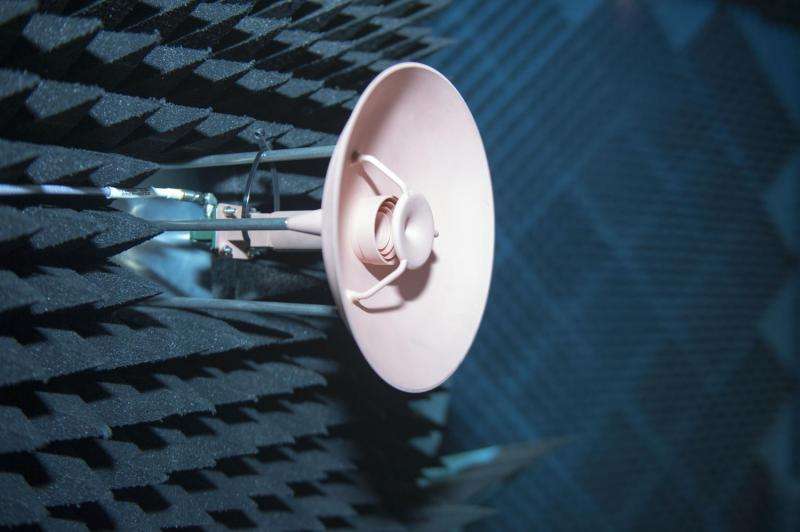

A prototype 3D-printed antenna being put to work in ESA's Compact Antenna Test Facility, a shielded chamber for antenna and radio-frequency testing.

"This is the Agency's first 3D-printed dual-reflector antenna," explains engineer Maarten van der Vorst, who designed it.

"Incorporating a corrugated feedhorn and two reflectors, it has been printed all-in-one in a polymer, then plated with copper to meet its radio-frequency (RF) performance requirements.

"Designed for future mega-constellation small satellite platforms, it would need further qualification to make it suitable for real space missions, but at this stage we're most interested in the consequences on RF performance of the low-cost 3D-printing process."

"Although the surface finish is rougher than for a traditionally manufactured antenna, we're very happy with the resulting performance," says antenna test engineer Luis Rolo.

"We have a very good agreement between the measurements and the simulations. Making a simulation based on a complete 3D model of the antenna leads to a significant increase in its accuracy.

"By using this same model to 3D print it in a single piece, any source of assembly misalignments and errors are removed, enabling such excellent results."

Two different antennas were produced by Swiss company SWISSto12, employing a special copper-plating technique to coat the complex shapes.

"As a next step, we aim at more complex geometries and target higher frequencies," adds Maarten, a member of ESA's Electromagnetics & Space Environment Division. "And eventually we want to build space-qualified RF components for Earth observation and science instruments."

Based at ESA's ESTEC technical centre in Noordwijk, the Netherlands, the test range is isolated from outside electromagnetic radiation while its inside walls are covered with 'anechoic' foam to absorb radio signals, simulating infinite space.

The range is part of ESA's suite of antenna testing facilities, intended for smaller antennas and subsystems, with larger antennas and entire satellites put to the test in its 'big brother', the Hertz chamber.

Provided by European Space Agency