Breakthrough for magnesium lightweight materials

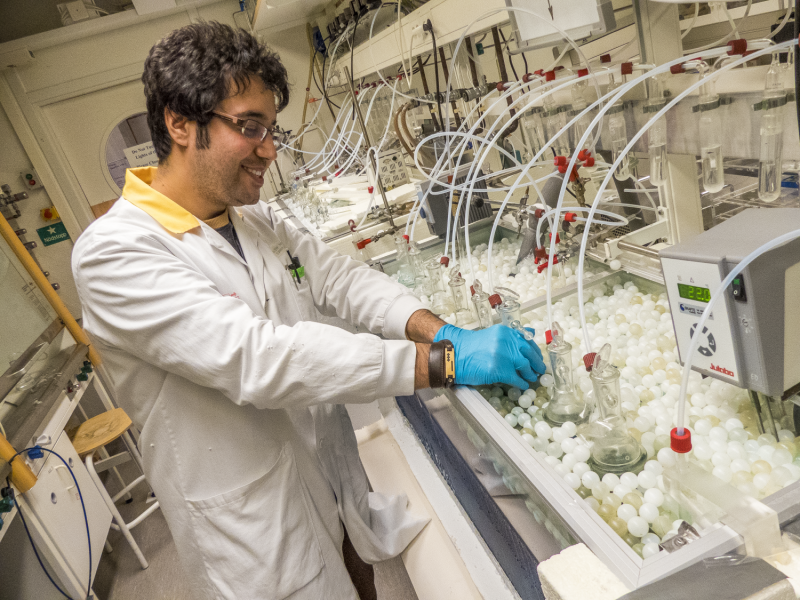

By changing the microstructure in magnesium alloys, Mohsen Esmaily, researcher in Atmospheric Corrosion at Chalmers University of Technology, has succeeded in improving possibilities for the transport sector to use these materials to decrease the weight of vehicles.

Magnesium is the lightest construction metal, but also the most reactive. This means that it is very sensitive to corrosion, i.e. it very easily reacts with its surroundings and rusts. This makes it difficult to use magnesium in corrosive environments, which means that the potential to use magnesium in cars to make them lighter is limited.

For more than a hundred years, magnesium producers have worked hard to improve the corrosion characteristics by developing new, more corrosion- resistant alloys, and also by developing various coatings. Mohsen Esmaily's research shows a completely new way to improve the corrosion resistance of the alloys by manipulating the microstructure of the material, thereby increasing possibilities to lower the weight of vehicles.

"In cars where every kilo of reduced weight is important, a transition to magnesium, which is 30 percent lighter than the most common lightweight metal today, aluminium, would mean a great step forward to reduce fuel consumption," says Mohsen Esmaily.

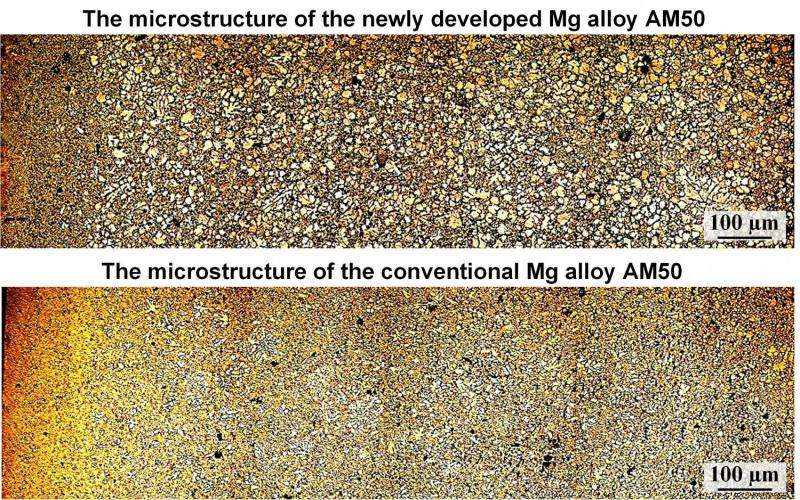

It was when he studied magnesium casts produced through a casting method called rheocasting that he discovered that the corrosion resistance of magnesium alloys produced this way, was up to four times better than the same material, when produced by conventional high pressure die casting. This new knowledge is based on a combination of unique exposure methods and a number of advanced analytical methods.

Rheocasting of magnesium alloys was developed at Jönköping University in order to increase the strength of the material, but Mohsen Esmaily's research shows that the technique also gives the alloys surprisingly good ability to withstand corrosion. With his research he shows the connection between the microstructure of the alloy and its corrosion resistance. Now that the connection has been mapped, new possibilities to optimize the microstructure for even better corrosion resistance have opened up.

"We will be able to create cast magnesium alloys that corrode much slower and that are stronger than ever before by controlling the microstructure of the alloy," Mohsen Esmaily says.

Over the past three years he has published over 30 articles, 22 of which as the main author. In these Mohsen Esmaily reports results that may increase the use of magnesium alloys and aluminium alloys in vehicles. Several of the articles have had a great impact in the field. One was the most downloaded article from the journal Corrosion Science in 2015. He has also been recognised by the Royal Swedish Academy of Engineering Sciences, which gave him SEK 50,000 for his work on magnesium corrosion.

More information: M. Esmaily et al. Influence of temperature on the atmospheric corrosion of the Mg–Al alloy AM50, Corrosion Science (2015). DOI: 10.1016/j.corsci.2014.10.040

Provided by Chalmers University of Technology