New 'RevoMaker' creates working products straight from 3-D printer

A new system allows a 3-D printer to produce functioning products with enclosed electronic and motorized components and customized devices such as a computer mouse molded to a user's hand.

"Toys work right out of the printer," said Karthik Ramani, Purdue University's Donald W. Feddersen Professor of Mechanical Engineering and a professor of electrical and computer engineering.

Because conventional 3-D printers create objects layer-by-layer from the bottom up, this poses a challenge when printing overhanging or protruding features like a figure's outstretched arms. They must be formed using supporting structures - which are later removed - adding time and material to the process. In traditional manufacturing the parts have to be assembled along with electronics packaging that goes on the inside.

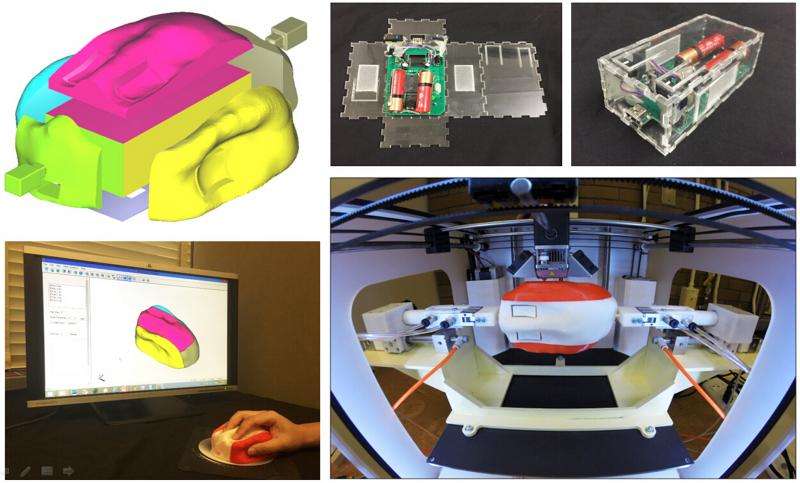

The new system, called RevoMaker, not only reduces the need for supporting structures, but also uses a new technique for multi directional printing. RevoMaker avoids assembly by printing the structure around the enclosed electronics. Different parts of the object are partitioned digitally and printed around a box that contains electronic and mechanical components.

"With a traditional 3-D printer you print on a planar print bed and the platform is fixed," said Raymond Cipra, a professor of mechanical engineering. "Our strategy is to replace the print bed with a laser-cut cuboid which can be rotated about an axis to provide orthogonal printing surfaces on each side of the volume. This cuboidal volume is also the space into which the electronics, motors, batteries are embedded before the printing process begins. Perhaps you could have multiple cuboids that you snap together in a customizable fashion."

Findings are detailed in a paper being presented during the Association for Computing Machinery's Symposium on User Interface Software and Technology (UIST), Nov. 8 to 11 in Charlotte, North Carolina. The paper was authored by doctoral student Wei Gao; postdoctoral research associate Yunbo Zhang; graduate student Diogo C. Nazzetta; Ramani; and Cipra.

"Our focus lies in enhancing an existing 3-D printer at minimal cost and complexity so that one does not have to use a more complex and expensive multi-axis machine," Gao said. "By just rotating the cuboid and using the printer's own X, Y, and Z-step control, we add much greater functionality and capability to the process. The process also enables side-surface functionalities, such as push-buttons, that also interact with housed modules in a compact volume "

Zhang said, "The cuboid base is generated inside any geometric model using our cuboidization algorithm. As the whole model is partitioned by the base, the algorithm computes the cuboid with as large a volume as possible cuboid to save printing material and with optimized orientation to reduce the necessary supporting material."

The plastic boxes could be shipped as flat templates and then unfolded and assembled in series to create a variety of products.

"The idea is that this is more personalized than traditional printing jobs, not mass manufactured," Ramani said. "I can envision products that are produced from modules and can be made for a small number of people. You go to the neighborhood business store, where they print customized products on demand."

The new system has been demonstrated by creating items with complex shapes, using different colors to show how the segments are printed separately but in a continuous process as the piece is turned and repositioned. In one project, a mouse was tailored to a person's hand by first creating a clay mold and then scanning it into a computer. The mouse was fully functioning out of the printer. Another project of a windup toy featured a spinning tail and glowing LED eyes.

The cuboid has to be repositioned at certain points during the printing process

Production time and the amount of material needed were reduced by as much as 37 percent, depending on the product.

"Using our methods we will soon be able to make things that actually walk out of the printer by themselves," Ramani said.

The research team developed both the hardware and software programming for the system. The team has no immediate plans to commercialize RevoMaker and sees this as only one step toward a more open community and platform.

"RevoMaker cleverly integrates several engineering innovations that advance the already incredible capabilities of additive manufacturing, making it more efficient and significantly easier to use by users of all ages," said Ed Morris, Director of America Makes, the National Additive Manufacturing Innovation Institute. "Potential applications of these technological advancements are equally incredible, from the fun of making custom toys, to use as a dynamic teaching tool, to empowering those with physical disabilities to create their own functional devices that enhance their quality of life."

More information: Wei Gao et al. The status, challenges, and future of additive manufacturing in engineering, Computer-Aided Design (2015). DOI: 10.1016/j.cad.2015.04.001

Provided by Purdue University