Researchers combine diamond and cubic boron nitride with a novel alloying process for a superhard material

Diamonds are forever, except when they oxidize while cutting through iron, cobalt, nickel, chromium, or vanadium at high temperatures. Conversely, cubic boron nitride possesses superior chemical inertness but only about half of the hardness of diamonds. In an attempt to create a superhard material better suited for a wide variety of materials on an industrial scale, researchers at Sichuan University in Chengdu, China, have created an alloy composed of diamonds and cubic boron nitride (cBN) that boasts the benefits of both.

"Diamond and cubic boron nitride could readily form alloys that can potentially fill the performance gap because of their affinity in structure lattices and covalent bonding character," said Duanwei He, a professor at Sichauan University's Institute of Atomic and Molecular Physics. "However, the idea has never been demonstrated because samples obtained in previous studies are too small to test their practical performance."

He and his colleagues at the University of Nevada and the Chinese Academy of Sciences detail their procedure this week in Applied Physics Letters.

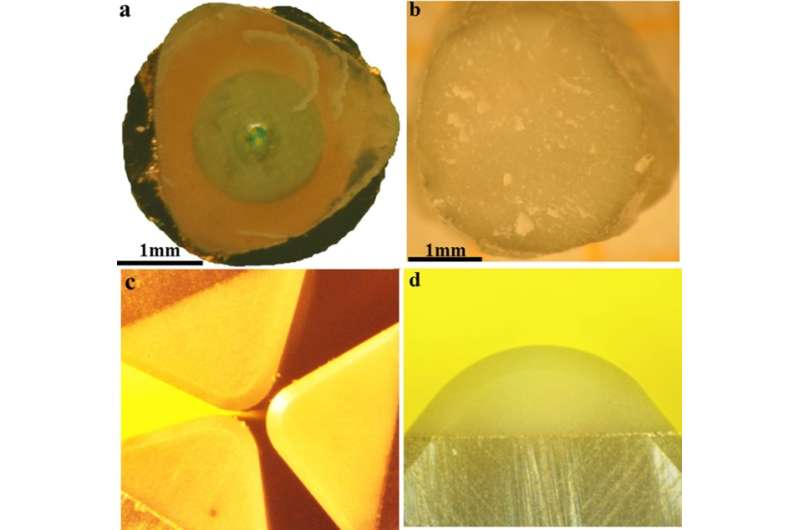

To synthesize diamond-cBN alloys, the researchers subjected a homogenous mixture of diamond and cubic boron nitride powder to a vacuum furnace at 1300 K for two hours, then pressed the material into 3.5 millimeter pellets under pressure greater than 15 gigapascals and temperatures above 2000 K. The pellets were then polished and sharpened into cutting implements.

The researchers tested the cutting performances of their alloy on hardened steel and granite bars on a computer numerical controlled lathe. They found that the diamond-cBN alloy rivaled polycrystalline cubic boron nitride's wear and tool life on the steel samples, and exhibited significantly less wear when cutting through granite. The alloy also demonstrated a more preferable high-speed cutting performance than either polycrystalline CBN or commercial polycrystalline diamonds.

Future work for He and his colleagues involves developing synthesis technology for centimeter-sized diamond-cBN alloy bulks to bring the process up to industrial-scale production.

More information: "Diamond-cBN Alloy: a Universal Cutting Method" by Pei Wang, Duanwei He, Liping Wang, Zili Kou, Yong Li, Lun Xiong, Qiwei Hu, Chao Xu, Li Lei, Qiming Wang, Jing Liu, and Yusheng Zhao. Applied Physics Letters , September 8, 2015. DOI: 10.1063/1.4929728

Journal information: Applied Physics Letters

Provided by American Institute of Physics