First series production vehicle with software control

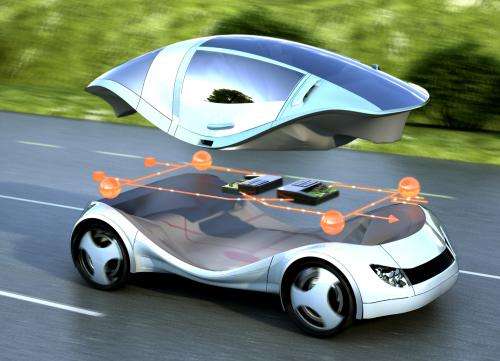

Siemens has unveiled the first electric series production vehicle with the central electronics and software architecture RACE. This technology, developed in the research project of the same name, replaces the entire control system with standard hardware and a kind of "operating system for automobiles." This is expected to massively reduce the development time for vehicles. Another advantage is that thanks to the standardized software base, additional functions can be retrofitted more easily and cheaply than before. Vehicle weight will also be reduced substantially.

Together with electric car manufacturer StreetScooter, experts at Corporate Technology, Siemens' global research unit, have equipped a series production vehicle with RACE technology. The abbreviation translates loosely as "Robust and Reliant Automotive Computing Environment for Future ears." A modern mid-range car has about 70 control devices installed in it and many meters of cable. There are a larger number of different interfaces and software applications in every vehicle that interoperate without a common software base. Currently the parking sensor, navigation and air-conditioning system, for example, each need their own control device, which is connected to other control devices.

The complexity of this architecture, which has grown over the years, will become less and less transparent and thus hinder innovation. In vehicles with RACE technology, there is now only one central processing unit controlling all functions. These are designed with multiple redundancy for reasons of safety. Development time for new vehicles has now been reduced by up to 30 percent thanks to the new capabilities of RACE.

Technology can also be used for trains and Smart Grids

The aim is that new functions should be easy to add in the future as well, in the same way as with Plug & Play on a computer. Today, this is hardly possible. To equip a car retroactively, say with a rear view camera, requires an immense amount of time and effort for testing. The installation and integration of new hardware in the existing communication system is nearly impossible, and the goal is to make this function more easily in the future. Thanks to RACE, tests for new functions can be integrated and performed digitally; new components will be connected to the RACE computer, for example via Ethernet. The component can be used after downloading the new software onto one of the control processors. Since functions no longer need a permanent connection to a control processor, it will be possible to install, for example, new infotainment or driving and assistance functions in the vehicle, ideally just in the form of software.

Less cable and fewer control devices will also have a positive impact on weight, and make cars less prone to faults. Electric cars in particular will profit from this because it increases their range and reduces running costs. The use of RACE is not, however, restricted to cars. The system architecture is also intended to be transferrable to multiple unit trains, smart grids or other complex systems.

Provided by Siemens