Cleaning desal plants with mathematics

A Curtin University engineering team has used a mathematical formula to help develop a system which could minimise down time and save on maintenance costs for desalination plants.

Associate Professor Hari Vuthaluru says conventionally operators need to periodically shut down reverse osmosis desalination plants to flush out salty deposits.

He says design improvements will make it possible for the systems to self-flush in the course of normal operations.

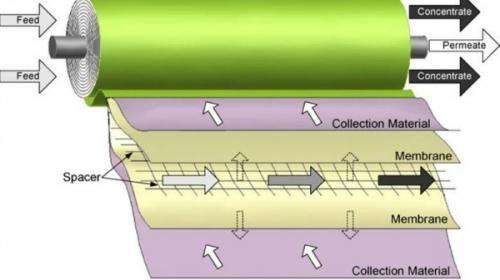

Reverse-osmosis plants operate by forcing sea water to flow between two parallel membranes that absorb water but not salt.

Operators then recover fresh water from the other side of each membrane.

The membranes are separated by a filament, similar to a wire mesh, which keeps the space open and allows water to flow between the membranes and out the other side.

However, salt tends to accumulate on the filament thereby clogging up the system.

A/Prof Vuthaluru has redesigned the filament, altering the water flow in such a way that some of the water flows backwards, keeping it clean.

He has devised a mathematical formula which varies the diameter of the top and bottom layers of wire in the mesh according to a set ratio.

In so doing, he says he has altered the angle at which water flows through the holes in the mesh, encouraging some of it to flow backwards out of the chamber.

He says so far they have only tested the technology with a single electrolyte: sodium chloride or common salt.

"In reality you will have calcium chloride and other materials also," A/Prof Vuthaluru says.

"We need to add another electrolyte also to see that everything is working as anticipated.

"We are going to build a small lab-scale Perspex experimental chamber where we are going to watch these flow phenomena by introducing a tracer into the membrane rig."

He says the system is expected to prolong operations and power consumption in terms of pumping energy requirements.

"We are almost there, it's a matter of testing these membrane modules at lab-scale before we can go out into the market."

A/Prof Vuthaluru says the technology should then attract investment from commercial interests.

"If any company supports our research, if they want to take if further, we are happy to go for this modular design with optimum spacer arrangements and then provide an efficient membrane operation," he says.

Reverse osmosis has been the favoured desalination technology worldwide for the last 15-20 years.

More information: "Impact of Feed Spacer Filament Spacing on Mass Transport and Fouling Propensities of RO Membrane Surfaces." DOI: 10.1080/00986445.2013.860525

Provided by Science Network WA