Simple, inexpensive fabrication procedure boosts light-capturing capabilities of tiny holes carved into silicon wafers

Increasing the cost-effectiveness of photovoltaic devices is critical to making these renewable energy sources competitive with traditional fossil fuels. One possibility is to use hybrid solar cells that combine silicon nanowires with low-cost, photoresponsive polymers. The high surface area and confined nature of nanowires allows them to trap significant amounts of light for solar cell operations. Unfortunately, these thin, needle-like structures are very fragile and tend to stick together when the wires become too long.

Now, findings by Xincai Wang from the A*STAR Singapore Institute of Manufacturing Technology and co-workers from Nanyang Technological University could turn the tables on silicon nanowires by improving the manufacturing of silicon 'nanoholes'—narrow cavities carved into silicon wafers that have enhanced mechanical and light-harvesting capabilities.

Nanoholes are particularly effective at capturing light because photons can ricochet many times inside these openings until absorption occurs. Yet a practical understanding of how to fabricate these tiny structures is still lacking. One significant problem, notes Wang, is control of the initial stages of nanohole formation—a crucial period that can often induce defects into the solar cell.

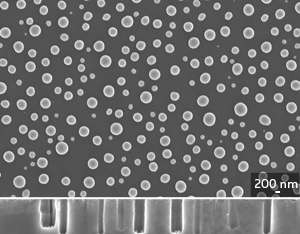

Instead of traditional time-consuming lithography, the researchers identified a rapid, 'maskless' approach to producing nanoholes using silver nanoparticles. First, they deposited a nanometer-thin layer of silver onto a silicon wafer which they toughened by annealing it using a rapid-burst ultraviolet laser. Careful optimization of this procedure yielded regular arrays of silver nanospheres on top of the silicon surface, with sphere size and distribution controlled by the laser annealing conditions.

Next, the nanosphere–silicon complex was immersed into a solution of hydrogen peroxide and hydrofluoric acid—a mixture that eats away at silicon atoms directly underneath the catalytic silver nanospheres. Subsequent removal of the silver particles with acid produced the final, nanohole-infused silicon surface (see image).

The team analyzed the solar cell activity of their nanohole interfaces by coating them with a semiconducting polymer and metal electrodes. Their experiments revealed a remarkable dependence on nanohole depth: cavities deeper than one micrometer showed sharp drops in power conversion efficiency from a maximum of 8.3 per cent due to light scattering off of rougher surfaces and higher series resistance effects.

"Our simple process for making hybrid silicon nanohole devices can successfully reduce the fabrication costs which impede the solar cell industry," says Wang. "In addition, this approach can be easily transferred to silicon thin films to develop thin-film silicon–polymer hybrid solar cells with even higher efficiency."

More information: Hong, L., Wang, X., Zheng, H., He, L., Wang, H., Yu, H. & Rusli, E. "High efficiency silicon nanohole/organic heterojunction hybrid solar cell." Applied Physics Letters 104, 053104 (2014). dx.doi.org/%2010.1063/1.4863965

Journal information: Applied Physics Letters