Supersonic spray delivers high quality graphene layer

A simple, inexpensive spray method that deposits a graphene film can heal manufacturing defects and produce a high quality graphene layer on a range of substrates, report researchers at the University of Illinois at Chicago and Korea University.

Their study is available online in the journal Advanced Functional Materials.

Graphene, a two-dimensional wonder-material composed of a single layer of carbon atoms, is strong, transparent, and an excellent conductor of electricity. It has potential in a wide range of applications, such as reinforcing and lending electrical properties to plastics; creating denser and faster integrated circuits; and building better touch screens.

Although the potential uses for graphene seem limitless, there has been no easy way to scale up from microscopic to large-scale applications without introducing defects, says Alexander Yarin, UIC professor of mechanical and industrial engineering and co-principal investigator on the study.

"Normally, graphene is produced in small flakes, and even these small flakes have defects," Yarin said. Worse, when you try to deposit them onto a large-scale area, defects increase, and graphene's useful properties—its "magic"—are lost, he said.

Yarin first turned to solving how to deposit graphene flakes to form a consistent layer without any clumps or spaces. He went to Sam S. Yoon, professor of mechanical engineering at Korea University and co-principal investigator on the study.

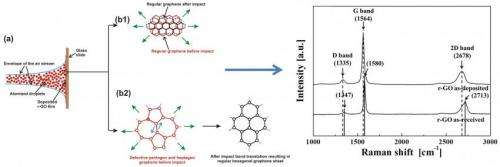

Yoon had been working with a unique kinetic spray deposition system that exploits the supersonic acceleration of droplets through a Laval nozzle. Although Yoon was working with different materials, Yarin believed his method might be used to deposit graphene flakes into a smooth layer.

Their supersonic spray system produces very small droplets of graphene suspension, which disperse evenly, evaporate rapidly, and reduce the tendency of the graphene flakes to aggregate.

But to the researchers' surprise, defects inherent in the flakes themselves disappeared, as a by-product of the spray method. The result was a higher quality graphene layer, as found in the analysis by another collaborator, Suman Sinha-Ray, senior researcher at United States Gypsum and UIC adjunct professor of mechanical and industrial engineering.

The researchers demonstrated that the energy of the impact stretches the graphene and restructures the arrangement of its carbon atoms into the perfect hexagons of flawless graphene.

"Imagine something like Silly Putty hitting a wall—it stretches out and spreads smoothly," said Yarin. "That's what we believe happens with these graphene flakes. They hit with enormous kinetic energy, and stretch in all directions.

"We're tapping into graphene's plasticity—it's actually restructuring."

Other attempts to produce graphene without defects or to remove flaws after manufacture have proved difficult and prohibitively expensive, Yarin said.

The new method of deposition, which allows graphene to "heal" its defects during application, is simple, inexpensive, and can be performed on any substrate with no need for post-treatment, he said.

Yarin and his Korean colleagues hope to continue their successful collaboration and foster the development of industrial-scale applications of graphene.

Journal information: Advanced Functional Materials

Provided by University of Illinois at Chicago