Biosensor based on a microelectromechanical system integrated with a photodetector

Label-free biosensors can be applied in many processes such as rapid diagnosis, tailor-made medication, and drug discovery. Label-free microelectromechanical system (MEMS)-based sensors detect target molecules by measuring the deflection of cantilevers caused by biomolecular adsorption.

However, it suffers from poor sensitivity because of the low conversion efficiency of linear transducing from the mechanical deflection to the readout signal.

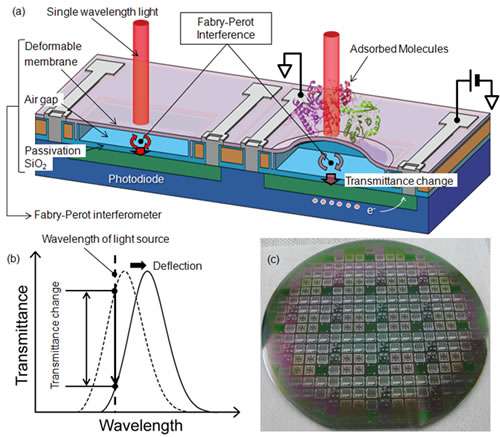

Kazuhiro Takahashi and colleagues at Toyohashi University of Technology have developed a biosensor based on a MEMS Fabry–Perot interferometer integrated with a photodiode, which utilizes the nonlinear optical transmittance change in the Fabry–Perot interference to enhance the sensitivity. The theoretical minimum detectable surface stress of the proposed sensor was predicted to be -1 µN/m, which is two orders of magnitude greater than that of the conventional MEMS sensor.

The Fabry–Perot sensor was fabricated using a 4-inch p-type silicon wafer. The photodiode was integrated into the silicon substrate using ion implantation of phosphorus. Sacrificial polysilicon was isotropically etched to form a freestanding membrane. Amino-methyl-functionalized parylene was coated on the membrane for immobilization of the biomolecules via electrostatic coupling.

After immobilizing anti-bovine serum albumin antibodies, the photocurrent change of 23.7 nA was measured, whereas no current shift was observed in the initial photocurrent as compared with that after washing with buffer solutions.

The MEMS Fabry–Perot interferometric sensor allows the use of a universal biochemical sensing platform in a label-free manner.

More information: Kazuhiro Takahashi, Hiroki Oyama, Nobuo Misawa, Koichi Okumura, Makoto Ishida, and Kazuaki Sawada. "Surface stress sensor using MEMS-based Fabry-Perot interferometer for label-free biosensing." Sensors & Actuators B 188, 393-399 (2013). (DOI): 10.1016/j.snb.2013.06.106

Provided by Toyohashi University of Technology