Soft metal weld makes for stronger infrastructure

Scientists have found applying a soft metal layer before welding hard metals can act as a sufficient buffer to address fatigue behaviour in welded metal.

The research investigated the effects of tensile over-load (OL) on high-strength low-alloy steels which are widely used in the mining industry for equipment like storage tanks and excavator buckets.

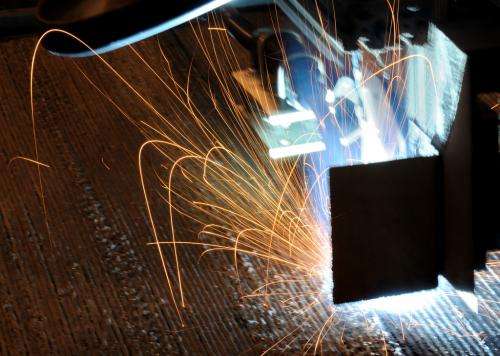

The scientists used flux cored arc welding and different widths of soft metals as the buffer layer to determine the fatigue life of the alloy and whether introducing a buffer layer would offset weakening of welded material.

They found that under the OL test conditions, the fatigue life of the weld-repaired alloy with a 10mm buffer layer was approximately six times greater than that of the weld-repaired steel without a buffer layer.

UWA School of Mechanical and Chemical Engineering's Xiaozhi Hu says often wear damage is localised so weld-repair, or filling up the damaged area, is more economical.

"It can create huge residual stresses along the welded interface and weld defects when hard weld metals are used directly onto the hard metal base," Winthrop Professor Hu says.

"When you do the welding you have the heat–affected zone and when that zone cools down it creates residual stress due to welding."

He says welding can reduce the toughness of the material by up to 50 per cent if it is not done correctly thereby making the metal very brittle and that all of these factors combined can make the weld site a problem area.

"So we tried welding with a soft metal layer because firstly it is quicker, you don't generate much of a heat-affected zone, then you put down the hard metals so the transition is better and there is less stress on the metal," W/Prof Hu says.

"Also the carbon content is neutralised, so you don't have much of a high carbon concentration region and that will make the material more brittle."

He says the buffer layer provides an extra structural design between a trans–metal and a weld metal, which are difficult to work with.

"It is almost like if you paint your house you will have your paint but sometimes you will apply an undercoat, and the undercoat acts as a transition and the buffer layer of metal plays a similar role to that undercoat," he says.

A buffer layer can be used in different situations including joining two metal structures or for repair work on offshore and onshore infrastructure.

More information: Chunguo Zhang, Xiaozhi Hu, Pengmin Lu, Gaiping Zhang, "Tensile overload-induced plastic deformation and fatigue behavior in weld-repaired high-strength low-alloy steel," Journal of Materials Processing Technology, Volume 213, Issue 11, November 2013, Pages 2005-2014, ISSN 0924-0136, dx.doi.org/10.1016/j.jmatprotec.2013.05.018.

Provided by Science Network WA