Looking inside food microstructures

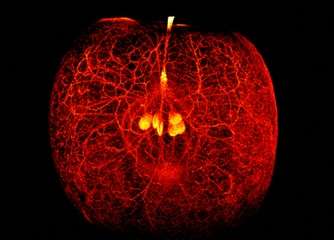

Food's microstructure can explain many of its characteristics—be it cake's sponginess, bread's crispness, cracker's crunchiness or fruits' inner gas and water transport system and even colour. Understanding such microstructure and how it changes during food processing is essential to produce high-quality food. To do so, an EU-funded project, called InsideFood and completed in May 2013, aimed at dramatically improving food microstructure measurement.

The project focused specifically on understanding the spatial distribution of food components, their texture and how to detect foreign material in food. To do so, the researchers developed novel instruments and software for inspecting food microstructure designed to be implemented in food processing plants. Scientists relied on food model systems, such as multiphase gels and foams. They also included information on actual foods such as cereal products or fresh and dried fruits.

Sugar and gluten-free products were the focus of special attention. This is because the Polish project partner, bread and cereal products manufacturer Chaber, based in Belsk Duży, wanted to commercialise them. "Texture largely depends on microstructure. Sugar and gluten are very important in the texture of bakery products," says project coordinator Bart Nicolai, professor biosystems engineering at the KU Leuven in Belgium. "The challenge is to create new sugar and gluten-free foods with the same texture," he adds.

The project scope is wider than just focusing on such applications. "The techniques we investigated are particularly suited to microporous foods that have a spongy structure, containing lots of air. [What was] new in our approach was the use of scanners and optical techniques already in use in biomedical research –for example to detect tumours– to investigate foods, "Nicolai tells CommNet, "We also applied large measuring equipment from fundamental physics research to explore common foods. On a global scale, we are setting a trend in 3D-visualisation of food microstructures."

The scientists used information from their observation to build mathematical models that describe how microstructures change under the influence of process situations. "Our final technical target is to design and optimise a food product [by computer]. A later step can be the production of foods by 3D-printing," Nicolai adds.

Experts welcome this approach, albeit with some nuances. "In my opinion the project teams has executed high-quality work," comments Marcel Paques, principal scientist at the Innovation Centre of dairy product company FrieslandCampina, in Wageningen, the Netherlands. "However, the work could also increase in value for the users in the food industry if the basic approach [were to] start from consumers and producers' needs," he adds.

In particular, Paques believes that the project's starting angle used was too analytical. Starting from the perspective of fulfilling consumer needs would have created a second drive, in the form of innovative products. Specifically, it would be preferable to select "favourably properties… that apply to a large product group and show generic aspects in multiple products, to support businesses with a large economic impact," he concludes.

Nevertheless, this project has brought significant progress to the field. "Although the relationship between microstructure and product functionality has been studied for many years by various research groups, new imaging techniques developed through this project will complement existing microscopy-based approaches," says Mark Auty, senior research officer at the food chemistry and technology department at the Teagasc Food Research Centre in Cork, Ireland.

And this is only the beginning. "This research could represent an exciting step forward in applying new techniques for non-destructive analysis of food products in their bulk state," Auty tells CommNet. "When we started, knowledge about 3D-visualisation of food microstructure was hardly existing," concludes Bart Nicolai, adding: "Mathematical models describing important physical processes were hardly available. We did a lot to fill this gap."

Provided by Youris.com