The shape of things to come

In his State of the Union address in February, President Obama told the American people that 3-D printing has the "potential to revolutionize the way we make almost everything."

By then, a Northeastern team of visionaries and digital technologists had already started planning to build a cutting-edge 3-D printing studio. The facility, they agreed, would be incorporated into the Digital Media Commons, an innovative media lab and digital creativity center located on the second floor of the Snell Library.

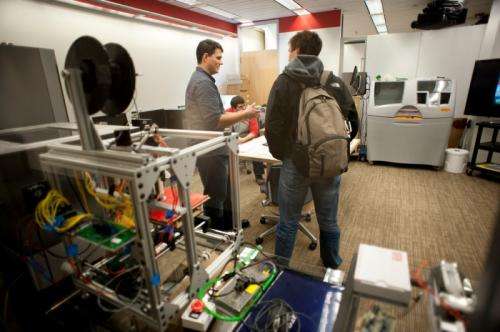

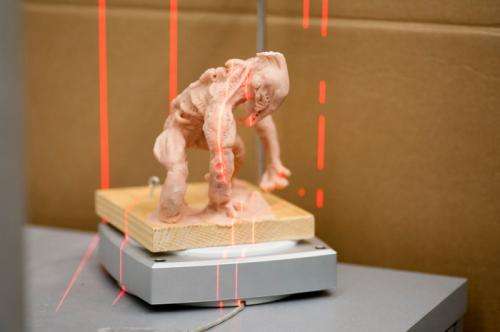

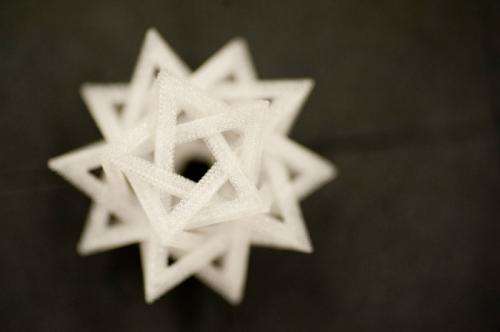

On Monday afternoon, the 3-D team celebrated the studio's soft launch by giving a score of students, faculty, and staff a tour of the new lab, which houses a full suite of 3-D fabrication and modeling technologies. 3-D printing, or "additive manufacturing," is the process wherein a digital model is transformed into a three-dimensional solid object by depositing successive layers of melted plastic or other materials.

Northeastern's 3-D Printing Studio is part of Snell Library's two-year transformation to address the need for greater access to educational technology; additional study spaces; and new, innovative opportunities for teaching and learning.

Monday's tour kicked off 3-D Printing Week, a series of events aimed at familiarizing the Northeastern community with the university's new state-of-the-art printing technology. On Wednesday and Thursday from 2–4 p.m., students and faculty may visit the 3-D studio to learn how to scan, print, and develop their own projects or incorporate 3-D technology into their courses.

Starting next week, the printing studio will be open for consultation hours from Monday through Friday. The devices will run 24/7 and jobs will be prioritized—a next-day classroom assignment will trump printing an iPhone case for personal use. The price to print will be based on a cost of the material, while the creation of the studio itself was made possible by the generosity of library donors.

The studio's designers view the lab as an interdisciplinary space for creating low-cost, high-quality intellectual property. "We're looking forward to seeing students and faculty take advantage of the studio in order to fulfill their inspirations," said Will Wakeling, dean of university libraries, who helped design the facility.

"Having a 3-D printing studio on campus gives students the opportunity to play with technology and find yet undiscovered career paths," added lab designer Janos Stone, a visiting professor in the College of Arts, Media, and Design.

In addition to Stone and Wakeling, the 3-D team comprises Richard Ranky, 3-D services specialist; Mark Sivak, assistant academic specialist in CAMD; and Patrick Yott, associate dean for digital strategies and services.

Ranky is a 2012 graduate of Northeastern's mechanical engineering doctoral program and the co-founder of 3-SPARK, a university spinoff specializing in 3-D printing technologies for the education and consumer markets. He will serve as the studio's fulltime staff member, a role that will include teaching students and faculty how to use its printing, scanning, and laser cutting equipment.

"We want to engage as many people as possible from all academic backgrounds," Ranky explained, echoing the sentiments of his co-designers. All someone needs to get started, he said, is a "sketch on a napkin."

Nick Behrens, a third-year mechanical engineering major, asked Ranky to turn his computer-aided design of a transdermal supplement device into a 3-D prototype. Behrens and a trio of teammates had designed the device for Northeastern's InnoWeekend, a 48-hour competition to create a new product or service.

"The quality of the 3-D printer was excellent and having access to a 3-D studio is a huge technological advancement for the university," Behrens said. "It's a great tool that will be sure to yield amazing results."

Provided by Northeastern University