Breakthrough adds a new dimension to printing (w/ Video)

(Phys.org) —Mechanical and Materials Engineering professor Jun Yang said there's a Chinese saying that "people cannot use a basket to draw water."

But what if you could make a basket that can do just that – and with a 3-D printer, no less. Thanks to research being developed by Yang and his colleagues, it is indeed possible.

Yang has developed a process called i3DP (initiator integrated 3D printing), an approach to printing materials with easy-to-modify surfaces. Normally, different inks – and different layers – require multiple 3D printers. The development of this process, however, puts it all in one machine.

"When we prepare the printing ink with an initiator, it's like a tree," Yang said. "The tree grows and the branches appear and each can have a different function. If you want to make a 3D structure conductive, or you want to insulate it from electromagnetic waves, we can modify it in that way."

A bromine-containing acrylate is added to a 3D printing resin, which acts as an initiator to allow polymer brushes to grow on the printed surface. The printed 3D structures are then grafted into useful materials – anything from aircraft and auto parts to bio-medical devices and even human bones – all using what is called surface-initiated atom transfer radical polymerization (ATRP).

This process also allows the structures to achieve antimicrobial property, which inhibits the growth of bacteria on the surface, necessary for biomedical applications. In addition, since the whole structure, including the inner surface, is bonded with the initiator, surface damage can be easily 're-painted' with the ATRP process.

While 3D printing for industry is nothing new, up until now, several printers with single-purpose inks were needed for different uses, which increased fabrication. With Yang's all-purpose ink, or 3D printing process, that is no longer the case.

"We just don't want a structure, but instead bring a function to that structure," Yang said. "We are very excited about this because this can solve big problems in industry occurring with 3D printing. I don't think there is an end of the line for this. It is very versatile."

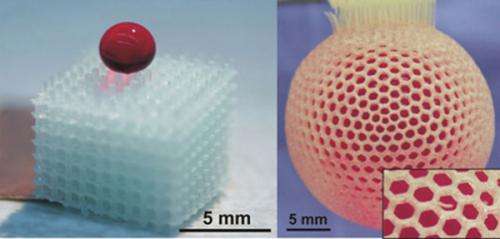

To test his approach, Yang fabricated two structures – a cube and a ball – each containing the polymer brushes and modified them to be either superhydrophobic (repels the water) or superhydrophilic (contains the water).

In testing the ball, the liquid was contained despite the 1.5mm pores in the mesh and despite even shaking the ball. In other words, the 'basket' held the water.

"If it were a regular ball, the water would leak out," Yang said. "But by modifying it, there is no leakage."

These applications could be used in something as simple as a shower curtain, allowing oxygen to pass through, but not water, or perhaps in industry, where windshields could be coated and potentially eliminating the need for wipers.

So far, the technique is only suitable for photopolymerization-based 3D printing, but Yang said he is working on printing smaller structures with greater accuracy.

"As engineers, we don't like to do research to be surprised," Yang said. "But there might be some things unexpectedly discovered along the way."

Provided by University of Western Ontario