Process devised for ultrathin carbon membranes

In the future, carbon nanomembranes are expected to be able to filter out very fine materials. These separating layers are ultrathin, consisting of just one layer of molecules. In the long term, they could allow to separate gases from one another, for example, filtering toxins from the air. At present, the basic research is concerned with the production of nanomembranes. A research team working with Professor Dr. Armin Gölzhäuser of Bielefeld University has succeeded in developing a new path to produce such membranes. The advantage of this procedure is that it allows a variety of different carbon nanomembranes to be generated which are much thinner than conventional membranes. The upcoming issue of the renowned research journal ACS Nano reports on this research success.

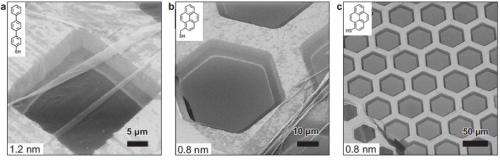

More than ten years ago, Professor Gölzhäuser and his then team created the groundwork for the current development, producing a carbon nanomembrane from biphenyl molecules. In the new study, the process was altered so as to allow the use of other starting materials. The prerequisite is that these molecules are also equipped with several so-called phenyl rings. For their new method, the researchers use the starting material in powder form. They dissolve the powder to pure alcohol and immerse very thin metal layer in this solution. After a short time the dissolved molecules settle themselves on the metal layer to form a monolayer of molecules. After being exposed to electron irradiation, the monolayer becomes a cross-linked nanomembrane. Subsequently the researchers ensure that the metal layer disintegrates, leav-ing only the nanomembrane remaining. 'Up until now, we have produced small samples which are are a few centimetres square', says Gölzhäuser. 'However, with this process it is possible to make nanomembranes that are as big as square metres.'

This new method is so special because the researchers can produce made-to-measure nanomembranes. 'Every starting material has a different property, from thickness or trans-parency to elasticity. By using our process, these characteristics are transferred onto the nanomembrane.' In this way, carbon nanomembranes can be produced to address many dif-ferent needs. 'That was not possible before now', says Gölzhäuser.

Furthermore, graphene can be made from nanomembranes. Researchers worldwide are ex-pecting graphene to have technically revolutionising properties, as it has an extremely high tensile strength and can conduct electricity and heat very well. The conversion from nanomembranes into graphene is simple for the Bielefeld researchers: The membranes have to be heated in a vacuum at a temperature of about 700 degrees Celsius. Gölzhäuser's team is working on the project with physicists from Ulm University, Frankfurt University and the Max Planck Institute for Polymer Research. The study has been funded by the Federal Ministry of Education and Research (BMBF) and the German Research Foundation (DFG).

More information: Polina Angelova, Henning Vieker, Nils-Eike Weber, Dan Matei, Oliver Reimer, Isabella Meier, Simon Kurasch, Johannes Biskupek, Dominik Lorbach, Katrin Wunderlich, Long Chen, Andreas Terfort, Markus Klapper, Klaus Müllen, Ute Kaiser, Armin Gölzhäuser und Andrey Turchanin: A Universal Scheme to Convert Aromatic Molecular Monolayers into Functional Carbon Nanomembranes, ACS Nano, dx.doi.org/10.1021/nn402652f, published online on 26 June 2013

Journal information: ACS Nano

Provided by University of Bielefeld