First with new environmentally beneficial technologies

Lulea University of Technology is the first in Sweden with a new technology that scales up production of nano-cellulose from wood residues. It may eventually give the forest industry profitable new products, such as nano-filter that can clean both gas and processwater, but also drinking water. Better health and a cleaner marine environment, both nationally and internationally, are some possible effects.

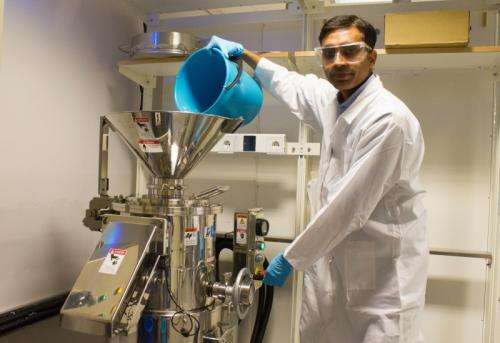

"There is a large interest in this by the industry, not least because our bionanofilter is expected to be of great importance for the purification of water, particularly internationally," says Aji Matthew, Assistant Professor at Luleå University of Technology who leads the EU-funded project.

On Tuesday, researchers at Luleå University of Technology demonstrated before representatives from the Industry and from research institutes how they have managed to scale up the process of manufacture of nano-cellulose of two different residues from the pulp industry. One is from Domsjö in Örnsköldsvik in the form of a fiber product that is grinded down to tiny nano fibers in a special machine. Through this process, the researchers have managed to increase the amount of the previous two kilograms per day to 15 kg per day. Another byproduct is nanocrystals that have been successfully scaled up from 50 to 640 grams / day. The process is possible to scale up and therefore highly interesting for the forest industry.

If this is successful we could add value to our waste. As it is, we earn almost no money on it and there is almost no place to store it, we give it away, says Anna Svedberg, product engineer at Domsjö Factories.

Bjorn Alriksson, research and development engineer at SP Processum, an organization that spans the entire forest industry when it comes to finding new products from the forest, he also sees great opportunities in the research.

"It is very relevant in the current situation because the paper industry does not run as good as in the past. There is a declining market, especially for newsprint paper and you need to find new products that you can produce from the forest and then Nanocellulose is a very interesting product," he says.

Nano Filter for purification of process water and drinking water is not the only possible product made of nano-cellulose since cellulose has much greater potential.

"Large-scale production of nano-cellulose is necessary to meet a growing interest to use bio-based nanoparticles in a variety of products," says Kristiina Oksman professor at Luleå University of Technology.

Nano filters is today developed at Imperial College, London, in close collaboration with the researchers at Luleå University of Technology.

"We have optimized the process to produce nano filters, we can control the pore size and thus the filter porosity. It's actually just a piece of paper and the beauty of this piece of paper is that it is stable in water, not like toilet paper that dissolves easily in water, but stable," says Professor Alexander Bismarck at Imperial College.

Provided by Lulea University of Technology