Bright light, big mirror: Precision X-ray focusing at NSLS-II

(Phys.org) —Why does a packet of electrons whizzing around a half-mile ring at nearly the speed of light need a state-of-the-art mirror? It's not to check its hair, that's for sure.

In order to deliver more of the X-ray light flung off by those speedy electrons to a sample awaiting investigation, the X-ray Powder Diffraction (XPD) beamline at the National Synchrotron Light Source II (NSLS-II) at Brookhaven National Laboratory (BNL) incorporates a mirror more than four-and-a-half feet long. It is polished so precisely that the difference in levelness from one end to the other is just one 50,000th of a degree.

It's the largest mirror in the world to achieve such flatness over its entire length. Because the high energy X-rays produced at XPD will need to reflect off the mirror at an incredibly low angle (typically 0.05 degree), the mirror has to be as long as the current manufacturing techniques allow while maintaining ultimate flatness in order to catch maximum X-rays from the source.

"This mirror will allow us to maximize the high-energy X-rays that the sample receives from the precious NSLS-II source that will be used at this beamline," said physicist Sanjit Ghose who oversaw the building of this one-of-a-kind mirror along with Eric Dooryhee the group leader for the XPD beamline. "It was a technical challenge, because the capability to make a mirror like this has never been tested."

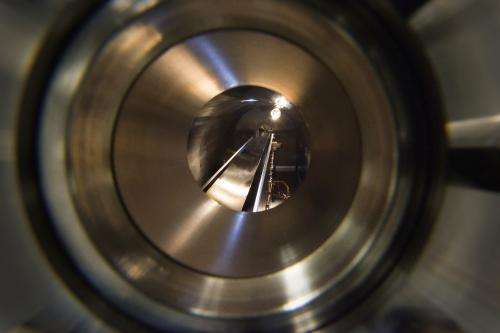

Getting silicon that long and perfectly polished is a difficult task. For the XPD beamline, a French company called WinlightX polished the mirror using ion beam figuring, a contactless smoothing method perfected only in the last few years. The purpose of the mirror is to focus all vertical arrays of X-rays of a particular energy to a small beam size and to make all the X-ray beams parallel. The mirror is kept under ultra-high-vacuum (one trillionth of atmospheric pressure) in a contaminant-free enclosure, and requires extremely high positional accuracy and mechanical stability that was achieved with very careful engineering of the mechanical parts.

"The state-of-the-art optical and mechanical performances of this gigantic instrument will allow for high-resolution, high-speed, and high-energy X-ray diffraction studies at the XPD beam line. We are taking advantage of this bright new source at NSLS-II and using an insertion device which gives us very high energy X-rays," Ghose said. "We will be able to do all kinds of in situ and in operando experiments on real life samples, which is so important because you can't truly understand the actual properties and functionality of a material under its real working conditions as long as its structure is just being studied in ambient or at-equilibrium conditions."

The X-rays at XPD will range from 30 to 70 Kiloelectron-Volts (KeV), and Ghose said the beamline will be perfectly suited for addressing many strategic questions like, for example, hydrogen storage, CO2 sequestration, advanced structural ceramics, catalysis, and materials processing. High-energy X-rays are highly penetrating and less damaging to the materials they're aimed at, so XPD will also be suitable for research into the inner workings of batteries as well as biological samples.

"When I came to Brookhaven, I was looking forward to an opportunity to build my own beamline," Ghose said. "I had never built a machine of that scale from start to finish before. This opportunity to serve a very broad and diverse research community on the Eastern coast of the U.S and around the world with this novel X-ray instrument is like getting a gift and it's very exciting."

But Ghose didn't install this mirror alone. BNL riggers and surveyors made immense contributions in the careful transportation and alignment of the mirror system during the installation process, and the vacuum group was a key part of getting the mirror vessel ready for use. Coordinating and sequencing all these activities and keeping this one-year long project on schedule were a major undertaking which also needed assistance from Christopher Stebbins.

"If you go to the trouble to get this one-of-a-kind mirror as flat as it is from the manufacturer, and then you don't get the expected performance after installation, you blame it on the preservation of the mirror surface quality and mechanics," he said. "We needed to recheck the surface quality using our own proper metrology and recheck that all the motors and actuators were still functioning well after the 4,000+ miles shipping to BNL. Without the commendable work of Mourad Idir on metrology, and the contributions of the XPD group members Hengzi Wang, John Trunk, and Wayne Lewis on mechanics and controls, this wouldn't have been possible. We needed everyone to make this work."

The effort made by the XPD team will pay off next year when NSLS-II sees first light. "We're pioneering new techniques and we will be able to deliver cutting-edge science with this beamline," Ghose said.

Provided by Brookhaven National Laboratory