July 9, 2013 report

New solarclave uses nanoparticles to create steam

(Phys.org) —A team of researchers at Rice University has developed a solar powered autoclave based on solar energy and metal and carbon nanoparticles. In their paper published in the journal Proceedings of the National Academy of Sciences, describing their device, the group explains how it was designed and ways it can be used in areas without electricity.

An autoclave is a device that uses steam to sterilize surgical tools—most models use electricity to generate the steam and as a result are heavy energy users. Such devices are not practical in remote areas with no electricity and because of that people all over the world in remote regions are at a high risk of developing infections from surgical procedures performed with unsterilized tools. To address this problem, the team at Rice has developed an autoclave based on solar power—a solarclave—with a major difference. Other autoclaves simply attempt to boil water using solar power, but there are limitations due to inefficient capture of radiated energy when using plain water. To get around this problem, the team added metal and carbon nanoparticles to the water.

The nanoparticles absorb solar radiation far more efficiently than water—that heat is then transferred directly to the water in which the nanoparticles reside. The result is a device that can make water hotter than can be done using traditional solar heaters and works faster as well. The steam that is created is routed to a pressure cooker where the tools are placed. After 30 minutes the tools are clean enough to pass U.S. FDA sterilization tests. Also, because the nanoparticles are too heavy to rise into the air with the steam that is created, they remain in the water, for use over and over again.

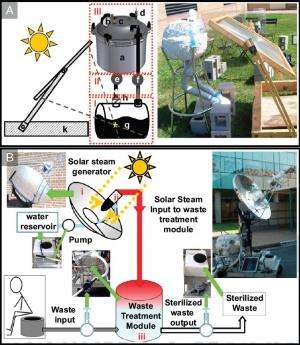

The team built two models of their device. One was a closed loop system where the water in the steam was recaptured and returned to the boiler after it cooled. Such a system they report would be ideal for tool sterilization. The second model was built to demonstrate the feasibility of using the same technique to treat water sewage waste. In such a system, waste water is heated and turned to steam to create sterile water clean enough to drink.

More information: Compact solar autoclave based on steam generation using broadband light-harvesting nanoparticles, PNAS, Published online before print July 8, 2013, doi: 10.1073/pnas.1310131110

Abstract

The lack of readily available sterilization processes for medicine and dentistry practices in the developing world is a major risk factor for the propagation of disease. Modern medical facilities in the developed world often use autoclave systems to sterilize medical instruments and equipment and process waste that could contain harmful contagions. Here, we show the use of broadband light-absorbing nanoparticles as solar photothermal heaters, which generate high-temperature steam for a standalone, efficient solar autoclave useful for sanitation of instruments or materials in resource-limited, remote locations. Sterilization was verified using a standard Geobacillus stearothermophilus-based biological indicator.

Journal information: Proceedings of the National Academy of Sciences

© 2013 Phys.org