Choosing a wave could accelerate airplane maintenance

Ultrasonic waves can find bubbles and cracks in adhesive bonds holding airplane composite parts together, and now aerospace engineers can select the best frequencies to detect adhesive failures in hard-to-reach places more quickly, thanks to Penn State researchers.

Different ultrasonic modes work best for different materials and configurations using the right one will locate more flaws with higher precision, according to the researchers. The selection process could save time and effort for engineers who perform maintenance on complex structures made from composite materials—like airplanes.

Adhesive bonds are better for attaching composite parts than nuts and bolts, which pierce and weaken structural integrity. But heavy operation can crack the glue, damaging the bond's effectiveness. Ultrasonic waves let engineers examine bonded regions without having to dismantle anything.

"This technique is very widely used in aerospace engineering because those structures require a very high reliability," said Baiyang Ren, postgraduate in engineering science and mechanics. "When something like an airplane or helicopter, bridge, ship has some component that fails suddenly, that could cause a severe accident."

For bonded regions located between easily accessible, wide surfaces, obtaining a clean readout is easy. Ultrasonic waves pass through the bonded intersection to a receiver on the other side without interference.

However, for bonds between inaccessible, irregularly angled surfaces, the ultrasonic wave will convert into a different mode by the time it enters and travels through the bonded region. This new wave mode may not be as sensitive to adhesive flaws.

"Usually…the mode conversion at this region is a blind thing for people," said Ren."We want to know (the mode conversion) so that we know how to inspect that bond."

There are thousands of ultrasonic modes, and for the best results, engineers have to choose one that will convert into the actual mode they want. Identifying the right one for a specific project through trial and error can be time-consuming.

Researchers devised a selection process to determine the best combination of ultrasonic modes for a given material by identifying the criteria for optimal frequencies and eliminating possibilities through a series of models and calculations.

"We want the mode to travel fast, travel longer, and be sensitive to this bond and still be received by some particular receiver," said Ren. "Each criteria will filter out some of the modes. After several steps, what things you have left are the modes that you want to try."

The results are available online in the International Journal of Adhesion and Adhesives.

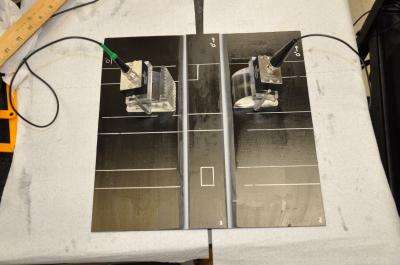

To evaluate the efficacy of the selection process, researchers tested two of the optimal modes on pieces of carbon-fiber-reinforced polymer, glued together with planned defects created by inserting Teflon into the bonded region.

They then compared the results with a readout produced by one of the discarded frequencies. The two modes predicted to be successful detected flaws at a much finer resolution than the discarded one. Cliff Lissenden, professor of engineering science and mechanics, also worked on this project.

Provided by Pennsylvania State University