ITER has arrival

On Monday 3 June the first ITER load made its way from the docks in Fos-sur-Mer, near Marseille, to the ITER construction site. Its precious cargo: 14.5 tons of copper conductor manufactured in China. The 737-metre copper "dummy" will serve to qualify the tooling and manufacturing processes of ITER's large and powerful poloidal field magnets. "This is only a small load," said the head of ITER's Magnet Division Neil Mitchell, "but we expect that it is the start of an avalanche of deliveries to the ITER site now that the production around the world is building up."

After 31 days on the sea, the freighter Lyra safely moored at the docks in Fos-sur Mer late Friday, 31 May. Precisely one month before, she had left Shanghai, China, with three large wooden boxes on board containing 737 metres of spooled copper conductor divided into three pieces. On Monday 3 June, the cargo passed customs and accomplished the final leg of its journey to be delivered at the ITER worksite, where it is now stored to await the deployment of the copper conductor during tests in the on-site winding facility for ITER's large poloidal field coils.

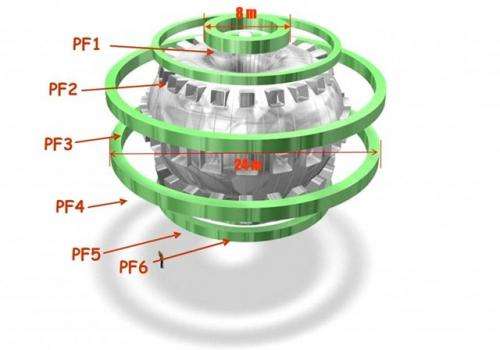

The lengths of dummy conductor were produced by the Institute of Plasma Physics (ASIPP) in Hefei. According to the Procurement Arrangement signed between the Chinese Domestic Agency and the ITER Organization, China will fabricate 64 conductors for ITER's poloidal field coils, including four dummy conductors. Russia and Europe will also contribute to poloidal field conductor procurement, which represents 1,224 tons of superconducting wire alone.

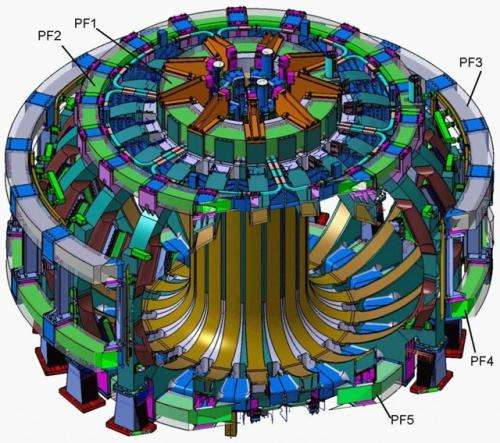

The poloidal field conductors for ITER will be made out of niobium-titanium (NbTi), an alloy that is too precious to be used for testing purposes. The dummy conductor delivered this week is composed of copper strands inserted into a stainless steel jacket (AISI 316LN). It will be used for validating the fabrication process of ITER poloidalfield coil number 5 (PF5).

"Each poloidal field coil is manufactured in a process that begins with the conductor spools that will be delivered on site," explains Piergiorgio Aprili from the European Domestic Agency Fusion for Energy: "First, a so-called double pancake is wound.

This is then vacuum-impregnated, stacked to form coils (which are also vacuum impregnated), and finally the completed coils are clamped and covered. Once the qualification of the process and of the tooling is successfully completed, the production of the real poloidal field coils can start."

Provided by ITER