Building 3-D fractals on a nano scale

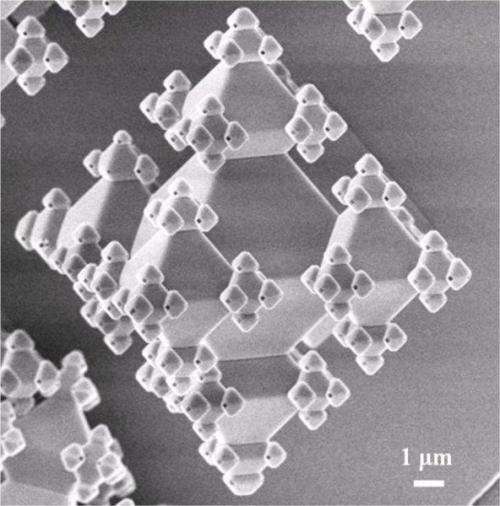

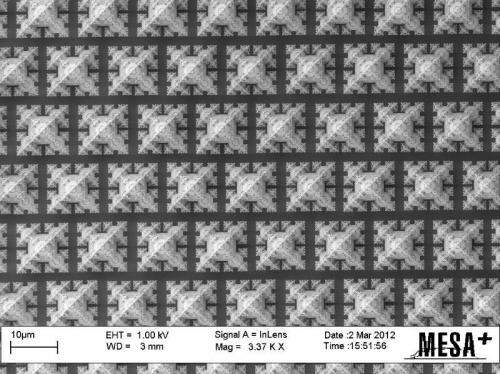

It starts with one 3D structure with eight planes, an octahedron. This repeats itself to smaller octahedra: 625 after just four steps. At every corner of a new octahedron, a successive octahedron is formed. A truly fascinating 3D fractal 'building' is formed on the micro and nano scale. It can be used for high performance filtering, for example. Scientists of the MESA+ Institute for Nanotechnology of the University of Twente in The Netherlands present these structures in the Journal of Micromechanics and Microengineering (JMM).

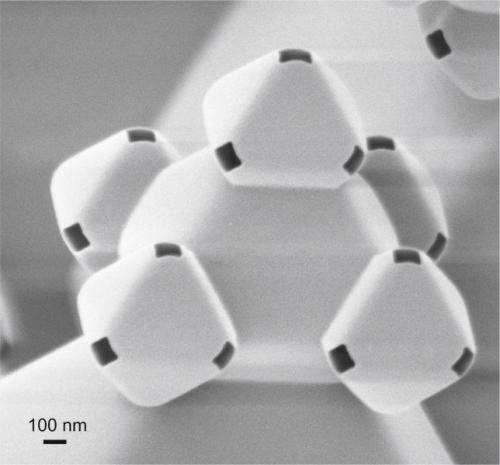

A fractal is a geometric structure that can repeat itself towards infinity. Zooming in on a fragment of it, the original structure becomes visible again. A major advantage of a 3D fractal is that the effective surface rises with every next step. Looking at the octahedra, after four steps the final structure is not much bigger than the original octahedron, but the effective surface has been multiplied by 6.5. The smallest octahedra are 300 nanometers in size, with on every corner a nano pore of 100 nanometer. Having 625 of these nano pores on a limited surface area, a very effective filer with low flow resistance is formed. The Dutch scientists also experiment with capturing living cells within these octahedral, to be able to study the interaction between the cells. Further interesting research is related to sending light through the octahedron structure: how will it interact?

Corner lithography

To be able to create the repeated 3D structure, the scientists developed a technique called 'corner lithography''. At first, a pyramid form is etched in silicon. The next step is applying a layer of silicon nitride on the pyramid. After removing this subsequently, a tiny bit of nitride stays in the corner of the pyramid, functioning as a 'stop'. When this is removed, the silicon underneath is etched through the tiny hole. Automatically, a structure is formed alongside the silicon crystal plane. This is the first octahedron, formed by 'auto alignment'. The process is repeated with a new layer of silicon nitride. The size of the new octahedra is determined by the etch period. In this case, every octahedron in the next step is half the size of the previous one. The advantage of corner lithography is its relative simplicity. No advanced technology is needed to create each individual nano pore. On the contrary: in just four steps thousands of fractals, each having 625 tiny holes can be processed on a wafer, in parallel. More than four steps is also possible, but this places higher demands on the etching process.

The research has been performed in the Transducers Science and Technology group, which is part of the MESA+ Institute for Nanotechnology of the University of Twente.

More information: Berenschot, E., Jansen, H. and Tas, N. Fabrication of 3D fractal structures using nanoscale anisotropic etching of single crystalline silicon, Journal of Micromechanics and Microengineering. iopscience.iop.org/0960-1317/23/5/055024/

Journal information: Journal of Micromechanics and Microengineering

Provided by University of Twente