January 18, 2013 feature

Electronics like it cold, and 30 K cryocooler delivers

(Phys.org)—For many electronic devices, colder is better. At low temperatures, electronic devices such as sensors and detectors operate with a higher efficiency and better overall performance than they do at room temperature. And superconducting devices, known for their zero electrical resistance, require extremely cold temperatures to operate. But in order to make cryogenic electronics more widespread, micro-sized cryogenic coolers need to become cheaper and more reliable. Addressing this challenge, scientists have designed and fabricated a micro-sized cryocooler that cools devices down to 30 K (-243 °C, -406 °F) in about an hour, and has a simple design that lends itself to high-yield fabrication.

The researchers, Haishan Cao from the University of Twente in Enschede, The Netherlands, and coauthors from Kryoz Technologies and Micronit Microfluidics, both in Enschede, as well as from the University of Twente, have published a paper on the new micro-sized cryogenic cooler in a recent issue of the Journal of Micromechanics and Microengineering.

The new cryocooler is a micro-sized version of a Joule-Thomson (JT) cryocooler, which cools by causing a high-pressure gas to expand as it flows from a high-pressure region to a low-pressure region. As James Joule and William Thomson discovered in 1852, a gas that expands in this way under certain conditions will cool down, a finding now known as the Joule-Thomson effect.

In the new study, the micro-sized cryocooler uses two stages to cool a device. The first stage involves a single-stage cryocooler device that other researchers at the University of Twente previously designed, which cools down to 100 K (-173 °C, -180 °F) using nitrogen as the gas. In the second stage, which cools down to 30 K, the researchers used hydrogen as the gas.

The reason for using two different gases is that the Joule-Thomson effect only works (i.e., produces a cooling effect) if the expanding gas is already cooled below a certain temperature called its inversion temperature. This critical temperature is different for different gases. If the gas is above this temperature, then expansion will cause the gas to warm up rather than cool down. Nitrogen has a higher inversion temperature than hydrogen, which is why the researchers used nitrogen in the pre-cooling stage, and then cooled the hydrogen through heat-exchange with the nitrogen until the hydrogen surpassed its inversion temperature of 205 K (-68 °C, -91 °F) so that it could be cooled by the second Joule-Thomson process.

"30 K is sufficiently cold to cool most electronic devices such as infrared detectors, low-noise amplifiers and high-temperature superconducting devices," Cao told Phys.org. "To cool superconducting devices based on Nb3Sn or NbTi, an even lower temperature is required. To reach even lower temperature using the Joule-Thomson effect, a helium stage is needed, in which the hydrogen stage works as a precooler for the helium stage."

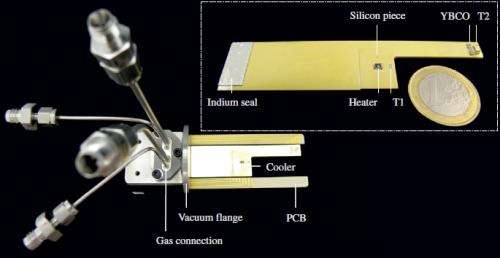

To demonstrate the feasibility of the new two-stage cryocooler, the researchers attached a YBCO film to the device to be cooled to its superconducting state. Starting from room temperature, the scientists showed that the nitrogen stage could cool the film to 94 K in about 20 minutes, and the hydrogen stage could cool the film to 30 K in an additional 40 minutes. During this cool-down process, the film reached its superconducting state, demonstrating the possibility for integrating the cryocooler with electronic devices.

One of the biggest advantages of the micro-sized cryocooler is that it has the potential be fabricated at low cost on a large scale. The cooler consists of just three glass wafers ranging in thickness from 145 to 400 μm, which are etched, stacked and bonded together. A stack of wafers can also be cut into multiple microcoolers using a dicing and powder blasting process. Another benefit is that the cryocooler operates at modest pressures, ranging from 0.1 MPa (room pressure) for the low-pressure region and 8.0-8.5 MPa for the high-pressure regions. When the pressure is higher, fabrication becomes more complex, in particular the bonding process.

"A 30 K micro cryocooler is the coldest micro cryocooler that has been published in academic journals," Cao said. "W. Little previously presented a seven-wafer stack two-stage JT micro cryocooler operating at 14 MPa with a cold-end temperature of about 30 K. Our two-stage 30 K JT micro cryocooler is operated with modest pressures and realized in a stack of only three wafers. Compared to three-wafer stack micro cryocoolers, seven-wafer stack micro cryocoolers are much more difficult to fabricate with acceptable yields. Furthermore, high gas pressures add more stringent requirements to the bonding process and severely add complexity to the development of a compressor for closed-cycle operation of the cryocooler."

The researchers hope that the relatively simple device requirements and the ability to cool to cryogenic temperatures (defined as temperatures below about 120 K [-153 °C, -244 °F]) will expedite cryogenic electronics applications. Such electronic and superconducting sensors and detectors could be especially useful in medical and space applications.

"In medicine, cryogenic electronic devices can be used in some diagnostic techniques, for example, tracing the spread of breast cancer cells," Cao said. "To determine whether the cancer has spread, the traditional way is to introduce radioactive particles into the body. But the radioactivity represents a health risk for both patient and medical personnel. Another method is using magnetic particles. However, existing detectors are not sensitive enough to measure the signal of the particles. The signal-to-noise ratio of the detectors could be greatly improved by cooling. Another application could be micro cryosurgery with miniaturized cold tips (for removing cancerous tissue).

"Applications of cryogenic electronic devices in space include scientific instrumentation, telecommunications and earth observation, and meteorology satellite. Many science missions in space use optical detectors that operate at cryogenic temperatures to increase their sensitivity. Radio-frequency devices (filters, delay lines, resonators and antennas) based on high-temperature superconductors have high potential to improve the energy efficiency of telecommunications systems or to reduce their size and weight. Earth observation missions require cryogenics because of the utilization of medium infrared detectors (typically operating around or just below 100 K) to image the earth surface.

"For these applications, the cooler should be small, low cost, low interference and have a very long lifetime. Joule-Thomson micro cryocoolers are excellent for this, because these have no cold moving parts and therefore can be scaled down to match the size and the power consumption of these devices."

In the future, the researchers plan to experiment with using gas mixtures in order to achieve lower temperatures at lower pressures.

"One of the future goals is to combine the micro cryocooler with a sorption compressor to realize a total micro system," Cao said. "Other future research topics in this area include three-stage microcryocoolers, micro cryocoolers using double expansion cycles and the use of a gas mixture as the working fluid. To reach temperatures near the boiling point of helium gas, it is necessary to use three stages. A nitrogen stage is used to precool a hydrogen stage, which works as a precool for a helium stage. Using a double expansion cycle, a Joule-Thomson cooler can achieve a lower temperature due to the reduction of the pressure drop in the low-pressure line. Compared to pure gas, mixed gases provide equivalent cooling power with significantly lower pressure ratio."

More information: H. S. Cao, et al. "Micromachined cryogenic cooler for cooling electronic devices down to 30 K." J. Micromech. Microeng. 23 (2013) 025014 (6pp). DOI: 10.1088/0960-1317/23/2/025014

Journal information: Journal of Micromechanics and Microengineering

Copyright 2013 Phys.org

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of Phys.org.