220-300C low-melting glass for hermetic sealing: Gold-tin solder level temperatures achieved

Hitachi today announced the successful development of a 220-300C low-melting temperature glass ("low-melting glass"). This glass was developed as a low temperature sealant which does not contain regulated materials such as lead which presents a high environmental load or easily vaporized halogens such as fluorine or iodine.

The glass developed will form part of the line-up of Hitachi Chemicals' environmentally-compatible low-melting vanadate glass series, "Vaneetect," achieving even lower temperature applications. It is relatively inexpensive compared to gold-tin solder, a conventional low-temperature sealant, and provides better sealing properties than adhesive resins against air and moisture. Further, as the low-melting glass developed can be used with metals, ceramics and resins, as well as melted with a variety of heat sources such as hot plates, infra-red lamps, lasers, etc., it also opens up new possibilities for device structure and process technology. Sample shipments from Hitachi Chemical are available from today.

In December 2009, Hitachi and Hitachi Chemical successfully developed the environmentally-compatible low-melting vanadate glass "Vaneetect" with a sealing temperature of 350-400C, as an alternative sealant to the toxic low-melting point glass containing lead and fluorine, or the relatively expensive gold-tin solder. In February 2012, Hitachi Chemical began mass production of Vaneetect, and it is now being applied in electronic devices, such as in crystal oscillators and MEMS devices. Gold-tin solder which can vacuum seal at around 300℃ continues to be used, however, in high quality electronic devices. Further, to improve the reliability of electronic devices which currently use adhesive resins, there is a growing demand in recent years for improved air/moisture resistance.

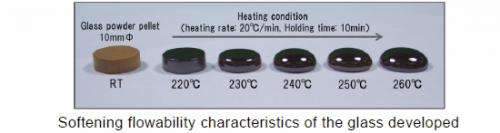

To address this need, Hitachi and Hitachi Chemical began development of an even lower temperature melting glass, and having discovered technology to control the glass structure, have succeeded in lowering the sealing temperature from 350-400C to 220-300C, and further improving resistance to water and vapor. Features of technology developed are as described below.

(1) Lower melting temperature technology

With the previous low-melting glass technology, a low melting temperature as well as high hermetic sealing, and resistance to water/vapor was achieved by doping the glass-network structure with cations which form weak bonds with oxygen ions and/or have a large ionic radius*6. Based on this technology, a technique was developed to control the glass-network structure to allow the stable introduction of silver ions with the effect of significantly reducing the melting temperature to 220-300℃. By adjusting the amount of silver ion introduced into the glass structure, it is also possible to control the sealing temperature. Further, by reducing cations which easily bond with water molecules, superior water/vapor resistance was also achieved.

(2) Features of the glass developed

- Environmental impact can be minimized as the glass does not contain lead or halogens.

- Due to a glass structure composed of only oxides, it can be heated and used as a seal in atmosphere, vacuum or in nitrogen gas.

- The glass may be heated with various heat sources such as hot plates, infra-red lamps, various lasers, etc. Further, thermal degradation in temperature-sensitive organic devices or electronic devices using resin substrates can be prevented using a laser source to only heat the low-melting glass portion.

Source: Hitachi

.jpg)