Fabrication of new elastic 'soft capsule' using nano-sized flakes

A research group headed by MANA Scientist Dr. Qingmin Ji of the National Institute for Materials Science (Japan), in joint study with Prof. Frank Caruso of the University of Melbourne, developed a new elastic capsule using an inorganic nanometer-thickness flake-shaped material (nanosheets). Tests of the new capsule demonstrated that the release duration of anticancer drugs and other drugs can be controlled freely and can also be extended by several times by using the newly-developed capsule.

Drug delivery systems (DDS) are considered an extremely promising technique for transporting drugs effectively and reliably to the site of pathologies such as cancers. As drugs are absorbed and decomposed in human bodies, they disperse widely, including areas other than the affected part, and it is not necessarily possible to control them to reach the intended part. For this reason, the development of micro-capsules and nano-capsules for controlled drug delivery is an urgent matter.

Until now, inorganic materials such as silica and organic materials such as fats and polymers have been used to form capsules. Inorganic capsules are hard, strong, and tough, but their structures are not easily adjusted to adapt to conditions. On the other hand, organic capsules are flexible and structural adjustment is possible, but they have the drawback of low mechanical strength. Thus, the development of a drug-carrier capsule structure with the advantages of both types had been desired.

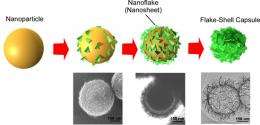

In this research, a “soft” capsule was developed by creating a fluffy assembly of nanosheets of silica, which is an inorganic material. While this capsule consists of a mechanically-stable inorganic material, free control of its structure is also possible.

This capsule expands and contracts when heated and cooled, and the size of the pores in the outer wall, which are formed by the spaces between the nanosheets and serve as passages for drug release, can be controlled over a wide range by adjusting pH to various levels. As a result, the sustained release time of the anticancer drug DOX was successfully extended by several times in comparison with conventional porous capsules having a simple structure. It was also possible to control the drug release duration and drug storage amount by changing the pore structure of the capsule, thereby changing the drug release routes, by advance treatment of the capsule under appropriate pH conditions.

These research results are to be announced in the online edition of the scientific journal Small.

Journal information: Small

Provided by National Institute for Materials Science