Fujitsu develops world's first technology for retrieving 3D CAD models with partially similar shapes

Fujitsu researchers have developed a technology for retrieving partially similar models from stored 3D CAD models.

In the manufacturing industry, for example, new parts designed using CAD models are not designed from scratch. By retrieving and reusing models with similar shapes from the existing models which incorporate prior design know-how, companies are able to shorten design time. Until now, while global shape retrieval has been possible, the inability to retrieve and reuse partially similar shapes has posed a challenge. With Fujitsu Laboratory's newly developed technology, 3D CAD models are automatically segmented into distinctive part models, such as protruding parts. Even if the orientation, size or position of the segmented parts differ, as long as the shapes are similar, they are determined to be similar, and can therefore be retrieved.

Because the new technology enables retrieved part models to be reused in combination with multiple other parts, design time can be shortened by 90% compared to designing from the ground up. This, in turn, helps to reduce design costs and enhance a product's competitiveness by quickly bringing it to market.

In order to quickly develop competitive products and rapidly bring them to market, companies in industries such as manufacturing need to shorten product design time by reusing existing 3D CAD models which incorporate prior design know-how, rather than designing models from the ground up. To achieve this target, technology that can efficiently retrieve reusable 3D CAD models is required.

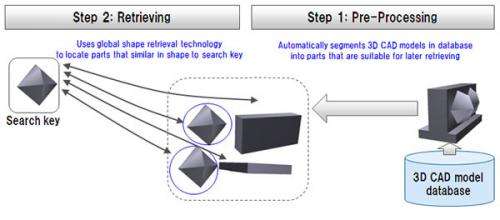

Existing 3D CAD model retrieval technology can perform text-based retrieval using part names and other keywords, as well as global shape retrieval (Figure 1) that retrieves 3D CAD models from the global shape.

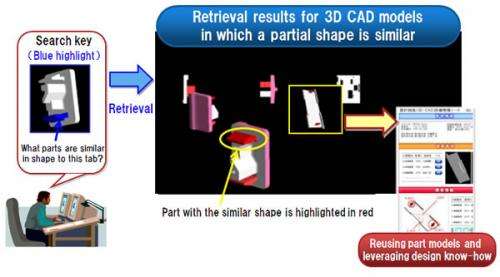

As can be seen with the tab example in figure 3, there is currently a need to shorten design time by reusing 3D CAD models with partially similar shapes. At the same time, because global shape retrieval employs the global shape of each model, the inability to retrieve 3D CAD models with partially similar shapes has posed a challenge.

Fujitsu Laboratories has developed a technology that can retrieve models with partially similar shapes from stored 3D CAD models. Because the new technology enables retrieved part models to be extracted and reused in combination with multiple other parts, design time can be shortened by 90% compared to designing from the ground up.

Key features of the technology are as follows:

1. Automatically segments each 3D CAD model into distinctive parts, such as protruding shapes

Fujitsu Laboratories has developed a technique that analyzes the elements composing a 3D CAD model, including the positional relationship between different surfaces, and automatically segments the model into distinctive parts that are suitable for later retrieval, such as protruding shapes. Furthermore, the company has developed a technology that automatically extracts shape features, such as concave and convex surfaces, from the segmented parts, and compares them to the shape features of the search key. As a result, even if the orientation, size or position of the models is different, as long as the shapes are similar, they can be determined to be similar. As part of the system's initial pre-processing (Step 1 in Figure 2), 3D CAD models stored in the database are segmented into part models through automatic segmentation process. After the designer specifies a shape to be used as a search key, similar parts are retrieved from the segmented models using global shape retrieval technology (Step 2 in Figure 2).

2. Retrieval via interactive interface

The designer-specified search key and 3D CAD models with partially similar shapes can be viewed together in a virtual 3D space (Figure 3). In addition, the system allows for efficient retrieval through color-coded highlighting of the similar parts.

This newly developed technology makes it possible to efficiently retrieve 3D CAD models containing shapes that are similar to a specified search key from a massive 3D CAD model database. With the new technology, 10,000 3D CAD models were automatically segmented into approximately 100,000 parts, and the 3D CAD models containing similar shapes to a specified search key could be retrieved in roughly three seconds, making it practical for real-world use. With the new technology, retrieved part models can be reused in combination with multiple other parts, for instance, making it possible to efficiently design new parts. As a result, the time required to design a part can be shortened by 90% compared to conventional technology. In addition, the new technology enables increased reusability of standard parts, making it possible to lower part-management costs.

Going forward, Fujitsu plans to pursue the commercialization of the new technology, and plans to incorporate it into Fujitsu's PLEMIA general design information management system before the end of FY2012.

Source: Fujitsu Corporation