Microlenses for 3-D endoscopes

Modern endoscopic techniques enable doctors to perform surgery without major incisions. Certain interventions require instruments with special 3-D optics. Researchers have developed an image sensor that transmits perfect 3-D images from inside the human body thanks to the use of microlenses.

The surgeon carefully guides the endoscope through the patient’s nasal cavity to the operation zone. It is a delicate procedure for which the surgeon has to prepare in detail before commencing the actual intervention. Where are the blood vessels that need to be avoided, what is the exact location of the cancerous tissue, and to what depth must the surgeon cut through the brain tissue to expose the area of interest? The camera integrated in the slender endoscope tube enables the surgeon to see every detail in sharp 3-D resolution – almost as if he were actually inside the patient’s brain. The stereoscopic vision provided by a 3-D endoscope considerably simplifies the work of neurosurgeons and other specialists. They can navigate a safe path through the tissue without the risk of collateral damage, and the work can be accomplished faster.

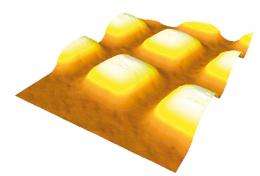

The ability to see inside the patient’s body in perfect 3-D is the result of work by researchers at the Fraunhofer Institute for Microelectronic Circuits and Systems IMS in Duisburg and the project partners in the EU project "Minisurg". The CCD sensors available in the past only provided low-resolution images. Thanks to the researchers’ work, CMOS image sensors of the type commonly incorporated in single-lens-reflex (SLR) cameras can now be used in medical applications. “To make this possible, we developed special microlenses,” explains IMS project manager Dr. Sascha Weyers. The secret lies in the optical design of the CMOS sensors, in which a cylindrical microlens is placed in front of every two vertical lines of sensors in the pixel configuration. A superimposed lens captures the light falling on the microlenses, which focus it on the pixels. The special feature of this arrangement is that the lens has two apertures, “rather like the right and left eye” says Weyers. In other words: two beams of light are captured by the lenses – that arriving from the left passes through the “left eye” to be focused on the right-hand vertical line of sensors, and vice versa. The two light rays cross underneath the lens arrangement. As a result, the CMOS sensor receives two sets of image data that are processed separately in the same way that the brain processes images coming from the left and right eye. A software program splits the incoming data and processes each set separately. Depending on the capabilities of the display system, the surgeon either sees the 3-D images directly on the screen or can see them when wearing polarized glasses.

It takes a special kind of microlens to ensure that the light rays are focused precisely on the sensor. In order to manufacture the lenses, the Fraunhofer engineers first had to calculate the optimum shape by means of simulations. To eliminate external factors, it had to be ensured that the lens was capable of clearly separating the right and left visual channels. In concrete terms this means ensuring that no more than five percent of the energy from one light ray is captured by the line of sensors serving the other channel – in signal transmission this is known as crosstalk.

The next task for the researchers was to adapt the conventional manufacturing process for microlenses to the requirements of the calculated lens shape. They also had to fulfill a number of requirements relating to the production of the miniature camera. They met the challenge, and the resulting chip is so small that it fits into a tube measuring no more than 7.5 millimeters in diameter. Together with the bundle of optical fibers that serves as the light source, the endoscope measures 10 millimeters in diameter – the perfect size for minimally invasive surgery.

Provided by Fraunhofer-Gesellschaft