Ames Laboratory partners with Iowa start-up under DOE innovation challenge

(PhysOrg.com) -- The U.S. Department of Energy's Ames Laboratory and Iowa Powder Atomization Technologies have joined forces in DOE's America's Next Top Energy Innovator challenge to create jobs in Iowa. The program gives start-up companies the opportunity to sign an option to license technologies created by national laboratories at reduced costs. IPAT signed an option agreement to license several materials processing technologies developed at the Ames Laboratory.

IPAT plans to use the technologies to make fine spherical titanium powder for use in military, biomedical and aerospace applications.

"The America's Next Top Energy Innovator program is a great opportunity to secure the option to use technologies IPAT needs to build a first-of-its-kind commercial-sized atomizer to create titanium powder," says Joel Rieken, IPAT co-founder.

"The America's Next Top Energy Innovator program shines a light on the many DOE-developed technologies that are just waiting for someone to come along to examine them, connect the dots between them, and use some creativity to come up with a business plan," continued Rieken, who is currently a graduate research assistant at the Ames Laboratory while he finishes his doctoral degree in materials science and engineering at Iowa State University.

Rieken, along with his business partner, Andrew Heidloff, who is a postdoctoral researcher at the Ames Laboratory, plan to use several technologies developed at Ames Lab that involve precision pouring of molten titanium and high-energy gas atomization to build a commercial system that will increase the efficiency of the titanium powder making process and, thus, lower the cost of the powder to manufacturers.

Titanium's strength, light weight, biocompatibility and resistance to corrosion makes it ideal for use in a variety of parts from small arms and military vehicle components to biomedical implants, aerospace fasteners and chemical plant valves.

"While titanium is more expensive than stainless steel, in many cases the lifetime of a titanium part outlasts a stainless steel part and becomes more cost effective in the long run" said Heidloff. "So, there's a growing interest in titanium applications. I think we will see it become an important strategic material."

Traditional part-making techniques like casting, where manufacturers melt and pour liquid metal into molds, can be troublesome when working with titanium because titanium tends to react with the materials used to form molds, requiring extensive machining to convert bulk castings to precise parts.

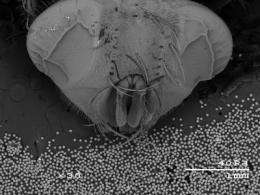

A possible solution to the casting mold problem is using gas atomization to make a fine, spherical powder form of titanium and using the powder to make parts. In gas atomization of titanium, the metal is melted using a standard commercial process then heated and precisely guided by an Ames Laboratory-developed pour tube into a high intensity atomization nozzle, also developed at Ames Lab. The metal is then sprayed out in a fine droplet mist. Each droplet quickly cools and solidifies, creating a collection of many tiny spheres, forming fine titanium powder. Manufacturers can then pour the powder into precise molds and press it together at high temperature to form parts.

"In addition to getting around the difficulties with using molten titanium, using titanium powder has the benefits of conserving processing time and energy, and it produces less waste material," said Rieken. "The overall process is better, except for the current problems of higher cost and lower availability of titanium powder. But those are the two problems IPAT is seeking to solve, and DOE's America's Next Top Energy Innovator challenge is supporting us in finding energy solutions and in creating jobs in a small business."

"IPAT had begun initial discussions with us for an option to license when the America's Next Top Energy Innovator program was announced. We're thrilled that the DOE program gave them an additional incentive to finalize the option agreement, and we're eager to see IPAT succeed at offering an energy-efficient process for making titanium powder," said Deb Covey, the Ames Laboratory's associate director for sponsored research administration.

IPAT is collaborating with the Quad Cities Manufacturing Laboratory and the Ames Laboratory in maturing the technology for the defense and commercial sectors.

The DOE Office of Science, Office of Fossil Energy, and the Iowa State University Research Foundation funded the original research on the gas atomizer technologies developed at Ames Laboratory.

Provided by DOE/Ames Laboratory