Scientists looking to burst the superconductivity bubble

(PhysOrg.com) -- Bubbles are blocking the current path of one of the most promising high temperature superconducting materials, new research suggests.

In a study published today, Monday, 16 may, in IOP Publishing's journal Superconductor Science and Technology, researchers have examined bismuth strontium calcium copper oxide (Bi2Sr2CaCu2Ox, Bi2212) – one of the most promising superconducting materials capable of creating large magnetic fields way beyond the limit of existing magnets – and found that its capabilities are limited by the formation of bubbles during its fabrication process.

Bi2212 is the only high temperature superconductor capable of being made into round wire, providing the preferred flexibility in magnet construction, and giving it potential uses in medical imaging and particle accelerators, such as the Large Hadron Collider in Switzerland.

For magnet applications, these wires must exhibit a high critical current density - the current density at which electrical resistance develops - and sustain it under large magnetic fields. This remains a stumbling block for utilising the huge potential of Bi2212 in the magnet technology as compellingly high critical current densities have not yet been achieved.

Previous studies have shown that a critical current varies widely between Bi2212 wire lengths – the critical current in wires that were 50 to 200m long was 20 to 50% lower than in 5 to 10cm long samples. This led the researchers, from the Applied Superconductivity Centre and the National High Magnetic Field Laboratory, Florida State University, to conclude that this variability must be caused by the connectivity of Bi2212 grains within the wires.

Bi2212 wires, made up of multiple filaments, are fabricated using the powder-in-tube (PIT) method in which Bi2212 powder is packed inside silver tubes and drawn to the desired size. The filaments of Bi2212 powder must firstly be melted inside their silver sheath and then slowly cooled to allow the Bi2212 to reform, greatly enhancing the critical current density.

As the processes between the critical melt and re-growth step is still largely unknown, the researchers decided to rapidly cool samples at different times in the melting process in order to get a snapshot of what occurs inside Bi2212 wires.

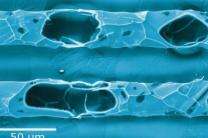

Using a scanning electron microscope and synchrotron X-ray microtomography, the researchers observed that the small powder pores, inherent to the PIT process, agglomerate into large bubbles on entering the melting stage.

The consequences of this are major as the Bi2212 filaments become divided into discrete segments of excellent connectivity which are then blocked by the residual bubbles, greatly reducing the long-range filament connectivity, and strongly suppressing the flow of current.

The new findings suggest that a key approach to improve the critical current density of the material would be to make it denser before melting.

Lead author Dr Fumitake Kametani, of The Applied Superconductivity Centre, Florida State University, said, "Our study suggested that a large portion of bubbles originates from the 30-40% of empty space, inevitable in any powder-in-tube process, which requires particle rolling to allow deformation of the metal-powder composite wire. "

"Densification of the filaments at final size - increasing the powder-packing density from 60-70% to greater than 90% - is an excellent way to reduce or eliminate the bubble formation. Various densification processes are now being tested."

More information: Bubble formation within filaments of melt-processed Bi2212 wires and its strongly negative effect on the critical current density, F Kametani et al 2011 Supercond. Sci. Technol. 24 075009 doi: 10.1088/0953-2048/24/7/075009

Abstract

Most studies of Bi2Sr2CaCu2Ox (Bi2212) show that the critical current density Jc is limited by the connectivity of the filaments, but what determines the connectivity is still elusive. Here we report on the role played by filament porosity in limiting Jc. By a microstructural investigation of wires quenched from the melt state, we find that porosity in the unreacted wire agglomerates into bubbles that segment the Bi2212 melt within the filaments into discrete sections. These bubbles do not disappear during subsequent processing because they are only partially filled by Bi2212 grains as the Bi2212 forms on cooling. Correlating the microstructure of quenched wires to their final, fully processed Jc values shows an inverse relation between Jc and bubble density. Bubbles are variable between conductors and perhaps from sample to sample, but they occur frequently and almost completely fill the filament diameter, so they exert a strongly variable but always negative effect on Jc. Bubbles reduce the continuous Bi2212 path within each filament and force supercurrent to flow through Bi2212 grains that span the bubbles or through a thin Bi2212 layer at the interface between the bubble and the Ag matrix. Eliminating bubbles appears to be a promising new path to raise the Jc of Bi2212 round wires.

Provided by Institute of Physics