Limit to nanotechnology mass-production?

(PhysOrg.com) -- A leading nanotechnology scientist has raised questions over a billion dollar industry by boldly claiming that there is a limit to how small nanotechnology materials can be mass produced.

In a paper published today, Thursday, 21 April, in IOP Publishing's journal Nanotechnology, Professor Mike Kelly, Centre for Advanced Photonics and Electronics, University of Cambridge, stated that you cannot mass produce structures with a diameter of three nanometres or less using a top-down approach.

This statement raises a major question concerning the billions of dollars that are poured into nanotechnology each year in the hope that the latest technology developed in the lab can make the transition to a manufactured product on the market.

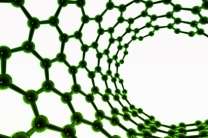

Nanotechnology is built on the ability to control and manipulate matter at the atomic and molecular level and has far reaching applications including the delivery of drugs into the body, increasing the efficiency of solar panels and improving methods of food packaging.

The overall goal when entering nanotechnologies into the market is low-cost, high-volume manufacturability, but at the same time, the materials' properties must be highly reproducible within a pre-specified limit, which Kelly states cannot happen below the 3nm limit when trying to make arrays.

The top-down approach to manufacturing, which Kelly states is limited, uses external tools to cut and shape large materials to contain many smaller features. Its alternative, the bottom-up approach, involves piecing together small units, usually molecules, to construct whole materials – much like a jigsaw puzzle – however this process is too unpredictable for defect – free mass production of arrays.

Kelly used statistical evaluation of vertical nanopillars - that have been suggested for uses in sensors and displays - as an example to demonstrate his theory. He states that the proof comes in two stages. The first is due to the fact that when materials are mass produced on such a small scale there will be a lot of variation in the size of different components.

As a result of this variation, the properties of the material will vary to an extent where the material cannot function to full capacity within an array.

Professor Kelly says, "If I am wrong, and a counterexample to my theorem is provided, many scientists would be more secure in their continued working, and that is good for science.

"If more work is devoted to the hard problem of understanding just what can be manufactured and how, at the expense of more studies of things that cannot be manufactured under the conditions of the present theorem, then that too is good for science and for technology."

More information: iopscience.iop.org/0957-4484/22/24/245303/

Provided by Institute of Physics