Software improves cement quality

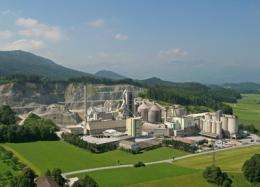

New control software predicts how cement mills will operate and continually optimizes the milling process. The results are improved cement quality and increased mill throughput. The software Sicement IT MCO has been installed for its first operation in one of the mills of a portland cement plant in the Bavarian city of Rohrdorf in south Germany. In the future, it will also control the remaining three mills.

Cement production is one of the most energy intensive production processes. It involves roasting the raw materials and additives to form a clinker, which is then ground into powder in a cement mill. This process requires almost 45 percent of the plant’s total power requirement. The quality of the cement depends on the ground material being as fine and as even as possible. As part of the quality control process, samples are normally taken at regular intervals and analyzed in the laboratory. The operating parameters, i.e. the quantity of fresh material fed in and the sifter rotation speed, are continually controlled in line with the fineness of the grinding stock and the throughput of the returns.

Sicement IT MCO continually controls both the product quality and the fineness of the cement produced. The expert system consists of a neural soft sensor incorporating components of the APC (Advanced Process Control) library from the Simatic PCS 7 and a multivariable controller (model predictive controller) integrated in PCS 7. The soft sensor is a software-based virtual sensor that collates multiple independent measured values and generates new values. It continually acquires current plant data such as the quantity of fresh material or the sifter rotation speed and utilizes this information to reliably predict the fineness of the ground cement. This prediction is regularly compared with current laboratory samples. Sicement IT MCO is replacing the old control system of a ball mill with a capacity of 60 tons per hour at the cement plant in Rohrdorf.

A similar expert system for the processing of copper ores has been developed by Siemens Industry in conjunction with the researchers at Corporate Technology. The system, which has been conceived as an extension of the gearless drive solution Simine Mill GD, also combines a knowledge-based approach with a predictive rule-based system—in this case to optimize water-based grinding processes.

Source: Siemens