Researchers create self-strengthening nanocomposite

Researchers at Rice University have created a synthetic material that gets stronger from repeated stress much like the body strengthens bones and muscles after repeated workouts.

Work by the Rice lab of Pulickel Ajayan, professor in mechanical engineering and materials science and of chemistry, shows the potential of stiffening polymer-based nanocomposites with carbon nanotube fillers. The team reported its discovery this month in the journal ACS Nano.

The trick, it seems, lies in the complex, dynamic interface between nanostructures and polymers in carefully engineered nanocomposite materials.

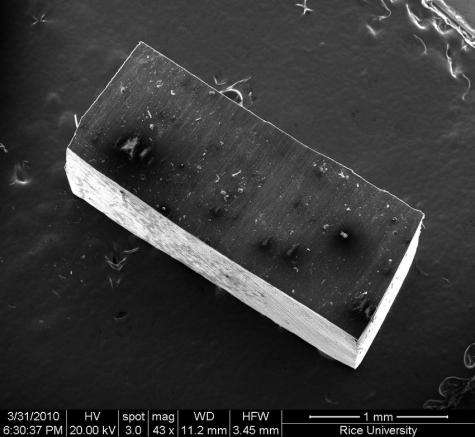

Brent Carey, a graduate student in Ajayan's lab, found the interesting property while testing the high-cycle fatigue properties of a composite he made by infiltrating a forest of vertically aligned, multiwalled nanotubes with polydimethylsiloxane (PDMS), an inert, rubbery polymer. To his great surprise, repeatedly loading the material didn't seem to damage it at all. In fact, the stress made it stiffer.

Carey, whose research is sponsored by a NASA fellowship, used dynamic mechanical analysis (DMA) to test their material. He found that after an astounding 3.5 million compressions (five per second) over about a week's time, the stiffness of the composite had increased by 12 percent and showed the potential for even further improvement.

"It took a bit of tweaking to get the instrument to do this," Carey said. "DMA generally assumes that your material isn't changing in any permanent way. In the early tests, the software kept telling me, 'I've damaged the sample!' as the stiffness increased. I also had to trick it with an unsolvable program loop to achieve the high number of cycles."

Materials scientists know that metals can strain-harden during repeated deformation, a result of the creation and jamming of defects -- known as dislocations -- in their crystalline lattice. Polymers, which are made of long, repeating chains of atoms, don't behave the same way.

The team is not sure precisely why their synthetic material behaves as it does. "We were able to rule out further cross-linking in the polymer as an explanation," Carey said. "The data shows that there's very little chemical interaction, if any, between the polymer and the nanotubes, and it seems that this fluid interface is evolving during stressing."

"The use of nanomaterials as a filler increases this interfacial area tremendously for the same amount of filler material added," Ajayan said. "Hence, the resulting interfacial effects are amplified as compared with conventional composites.

"For engineered materials, people would love to have a composite like this," he said. "This work shows how nanomaterials in composites can be creatively used."

They also found one other truth about this unique phenomenon: Simply compressing the material didn't change its properties; only dynamic stress -- deforming it again and again -- made it stiffer.

Carey drew an analogy between their material and bones. "As long as you're regularly stressing a bone in the body, it will remain strong," he said. "For example, the bones in the racket arm of a tennis player are denser. Essentially, this is an adaptive effect our body uses to withstand the loads applied to it.

"Our material is similar in the sense that a static load on our composite doesn't cause a change. You have to dynamically stress it in order to improve it."

Cartilage may be a better comparison -- and possibly even a future candidate for nanocomposite replacement. "We can envision this response being attractive for developing artificial cartilage that can respond to the forces being applied to it but remains pliable in areas that are not being stressed," Carey said.

Both researchers noted this is the kind of basic research that asks more questions than it answers. While they can easily measure the material's bulk properties, it's an entirely different story to understand how the polymer and nanotubes interact at the nanoscale.

"People have been trying to address the question of how the polymer layer around a nanoparticle behaves," Ajayan said.

"It's a very complicated problem. But fundamentally, it's important if you're an engineer of nanocomposites.

"From that perspective, I think this is a beautiful result. It tells us that it's feasible to engineer interfaces that make the material do unconventional things."

More information: Read the abstract at pubs.acs.org/doi/abs/10.1021/nn103104g

Provided by Rice University