March 17, 2011 weblog

MSU researchers create a new engine prototype (w/ video)

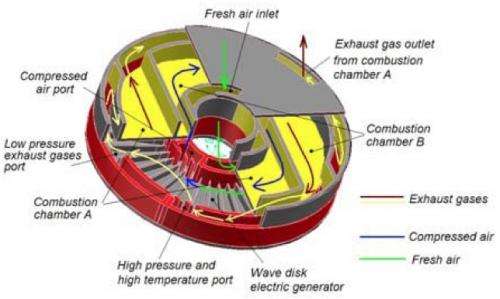

(PhysOrg.com) -- Researchers at Michigan State University have built a prototype, based on the research first released in 2009, of the Wave Disk Generator -- an engine that does not have pistons, crankshafts or valves.

This new model, which does away with the internal combustion engine of the past, has the potential to reduce auto emissions up to 90 percent, when compared to the current emissions level. This is because the engine uses roughly 60 percent of its fuel for propulsion, when you compare this to the typical cars engine that uses only 15 percent of fuel for propulsion, we can see how the increase is possible.

The new engine prototype is built with a disc-shaped shock wave generator that is about the size of a sauce pan, and will require no transmission system, cooling system, emissions regulation or fluids, which means that you will end up not only doing something good for the planet, but you will end up with less in maintenance costs, if this new prototype ever comes to the market.

The engine works like this: a rotor, with a wave-like pattern carved into channels. The fuel and air enter and mix through the central inlets. The rotor then spins, blocking the exit of gasses. As the pressure builds it will generate a shock wave that will compress the mixture. Once it is ignited an outlet opens to let the hot gases escape, and your car can move as usual.

The engine prototype was shown off by Norbert Müller and other colleagues at Michigan State University at a meeting with the Department of Energy’s Advanced Research Projects Agency.

© 2010 PhysOrg.com