Layered metallic hydroxide crystals traps carbon dioxide gas at elevated temperatures

'Scrubbing' carbon dioxide (CO2) from industrial exhaust gases is one of the critical steps needed to reduce CO2 emissions. It remains a major challenge for researchers, however, to find materials that can reliably soak up CO2 under the extreme conditions common to real-world industrial processes. A study by Jizhong Luo and co-workers from the A*STAR Institute of Chemical and Engineering Sciences in Singapore now promises to help mitigate CO2 emissions by uncovering never-before-seen structural details of high-temperature sorption materials called layered double hydroxides (LDHs).

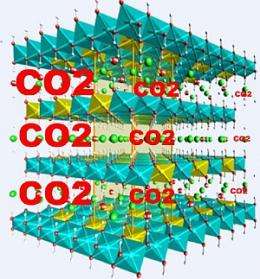

Composed of positively charged sheets of metal oxides interspersed with relatively open spaces holding anions and water molecules, LDHs have large, active surfaces that can react with CO2 and transform the gas into solid carbonate ions. Recently, scientists have used LDHs as part of an innovative technology called the sorption-enhanced water-gas shift that combines high-temperature hydrocarbon processing with CO2 removal in a single step. However, when LDHs reach their adsorption limits, they must be regenerated by heating to temperatures high enough to induce an internal structural transformation—a process known as calcination that can eventually destabilize the metal oxide layers.

Luo and his co-workers set out to understand the high-temperature performance of these adsorbents by adjusting the chemical composition of a typical magnesium–aluminum LDH. The researchers replaced the triply charged aluminum cations with iron, gallium and manganese cations and systematically observed how these substitutions affected structure, adsorption and thermal stability. Their results revealed, for the first time, the role such metal species play in LDH-based CO2 fixation.

Surprisingly, the researchers found that the new cations influenced the physical properties of the LDH more than its chemical behavior. “Generally, people may think that differences in chemical composition between LDHs will lead to different CO2 adsorption sites, and therefore different carbon capture capacities,” notes Luo. “However, our research demonstrates that the temperature-dependent structural evolution of LDHs is a much more important parameter.” Luo and his co-workers showed that distinct calcination temperatures for each LDH compound, as well as a unique quasi-amorphous phase, are key to maximizing CO2 adsorption levels.

The empirical ground-rules laid out by this study should help researchers select even better candidates for industrial CO2 scrubbers. “High-temperature CO2 adsorbents are a hot topic right now in carbon capture and sequestration,” Luo says. “In the future, we plan to use combinations of triply charged metal cations to better tune the CO2 capturing performance of LDHs.”

More information: Wang, Q. et al. The effect of trivalent cations on the performance of Mg-M-CO3 layered double hydroxides for high-temperature CO2 capture. ChemSusChem 3, 965–973 (2010). dx.doi.org/10.1002/cssc.201000099

Provided by Agency for Science, Technology and Research (A*STAR)