Self-assembling polymer arrays improve data storage potential

(PhysOrg.com) -- A new manufacturing approach holds the potential to overcome the technological limitations currently facing the microelectronics and data-storage industries, paving the way to smaller electronic devices and higher-capacity hard drives.

"In the past 20 to 30 years, researchers have been able to shrink the size of devices and the size of the patterns that you need to make those devices, following the use of the same types of lithographic materials, tools and strategies, only getting better and better at it," says Paul Nealey, director of the University of Wisconsin-Madison Nanoscale Science and Engineering Center (NSEC).

Now, those materials and tools are reaching their fundamental technical limits, hampering further performance gains. In addition, Nealey says, extrapolating lithography — a process used to pattern manufacturing templates — to smaller and smaller dimensions may become prohibitively expensive. Further advances will require a new approach that is both commercially viable and capable of meeting the demanding quality-control standards of the industry.

In a collaborative effort between academic and industry, chemical and biological engineering professors Nealey and Juan de Pablo, and other colleagues from the UW-Madison NSEC partnered with researchers from Hitachi Global Storage Technologies to test a promising new twist on the traditional methods. In the Aug. 15 issue of the journal Science, the team demonstrates a patterning technology that may revolutionize the field, offering performance improvements over existing methods even while reducing the time and cost of manufacturing.

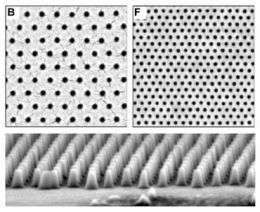

The method builds on existing approaches by combining the lithography techniques traditionally used to pattern microelectronics with novel self-assembling materials called block copolymers. When added to a lithographically patterned surface, the copolymers' long molecular chains spontaneously assemble into the designated arrangements.

"There's information encoded in the molecules that results in getting certain size and spacing of features with certain desirable properties," Nealey explains. "Thermodynamic driving forces make the structures more uniform in size and higher density than you can obtain with the traditional materials."

The block copolymers pattern the resulting array down to the molecular level, offering a precision unattainable by traditional lithography-based methods alone and even correcting irregularities in the underlying chemical pattern. Such nanoscale control also allows the researchers to create higher-resolution arrays capable of holding more information than those produced today.

In addition, the self-assembling block copolymers only need one-fourth as much patterning information as traditional materials to form the desired molecular architecture, making the process more efficient, Nealey says. "If you only have to pattern every fourth spot, you can write those patterns at a fraction of the time and expense," he says.

In addition to shared intellectual contributions, the collaboration between the UW-Madison and Hitachi teams provided very clear objectives about creating a technology that is industrially viable. "This research addresses one of the most significant challenges to delivering patterned media — the mass production of patterned disks in high volume, at a reasonable cost," says Richard New, director of research at Hitachi Global Storage Technologies. "The large potential gains in density offered by patterned media make it one of the most promising new technologies on the horizon for future hard disk drives."

In its current form, this method is very well-suited for designing hard drives and other data-storage devices, which need uniformly patterned templates — exactly the types of arrangements the block copolymers form most readily. With additional advances, the approach may also be useful for designing more complex patterns such as microchips.

"These results have profound implications for advancing the performance and capabilities of lithographic materials and processes beyond current limits," Nealey says.

Provided by University of Wisconsin-Madison