Nano-Sun: From Traditional Printing to High Resolution Nano-Printing

IBM researchers in collaboration with scientists from the ETH Zurich have demonstrated a new, efficient and precise technique to “print” at the nanoscale.

The method, which allows the scientists to place individual particles precisely where they want them, could advance the development of nanoscale biosensors, ultra-tiny lenses that can bend light inside future optical chips, and the fabrication of nanowires that might be the basis of tomorrow’s computer chips.

Though still a few years from being used widely, the new technique shows promise for real world applications outside of the lab without major profound new inventions, and could lead to high-volume manufacturing techniques for nanostructures inside chips and other devices that are more efficient and cost less than today’s methods.

“This method opens up new ways to precisely and efficiently position various kinds of nanoparticles on different surfaces, a prerequisite for exploiting the unique properties of such nanoparticles and for making their use economically feasible,” explains Heiko Wolf, researcher in nanopatterning at IBM’s Zurich Research lab.

The achievement, published in the September issue of the journal Nature Nanotechnology, offers a promising and powerful new tool for use in a wide range of fields and industries such as biomedicine, electronics and IT that seek ways to exploit the often unique properties of so-called nanoparticles, which are defined as particles smaller than 100 nanometers.

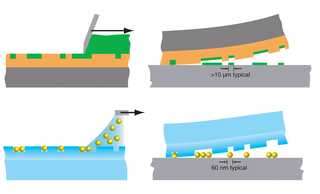

Until now, standard top-down micro-fabrication techniques produce such tiny particles by in effect carving them out of a bigger piece of material. Printing, in contrast, adds ready-made nanoparticles onto a surface in a very efficient way and allows for different types of materials such as metals, polymers, semiconductors, and oxides to be combined in one process.

For the first time, the researchers printed particles as tiny as 60 nanometers -- roughly 100 times smaller than a human red blood cell -- with single-particle resolution to create nano-patterns ranging from simple lines to complex arrangements. Translating the resolution of these particles into a traditional printing term known as “dots per inch” or dpi, a standard measure that defines how many individual spots of ink can be printed on a certain area, the nanoprinting method yields 100,000 dots per inch, whereas common offset printing today operates at 1,500 dpi.

To demonstrate the efficiency and the versatility of their method, the researchers chose to print Robert Fludd’s 17th-century image of the sun, the alchemists’ symbol for gold. Quite fittingly, it is printed out of roughly 20,000 gold particles, each of them 60 nanometers in diameter. The printing method precisely placed one particle per dot, thus creating the smallest piece of artwork ever printed from single pigment particles.

Nanoprinting Applications

In biomedicine this printing process could, for example, be applied to the printing of large arrays of biofunctional beads that can detect and identify certain cells or markers in the body. One example could be rapid screening for cancer cells or heart attack markers. As part of new point-of-care diagnostic devices, regular arrays of functional beads could enable a fast and automated read-out that only needs the tiniest amounts of samples.

Nanoparticles can also interact with light. With the new method, optical materials with new properties could be printed, for example, for use in optoelectronic devices. So-called “metamaterials” could be created in which the printed structures are as small as the wavelength of the light and therefore act as if they were a single lens with unusual properties.

Moreover, the method holds promise for semiconductors. In one experiment, the researchers achieved the controlled placement of catalytic seed particles for growing semiconducting nanowires. Such nanowires are promising candidates for future transistors in microchips.

Printing on the Nanoscale

“In traditional gravure printing, a doctor blade is used to fill the recessed features of a printing plate with ink, in which pigment particles are randomly dispersed,” explains Tobias Kraus, of the nanopatterning team in Zurich. “In our high-resolution printing, a directed self-assembly process controls the arrangement of nanoparticles on the printing plate or template. The entire assembly is then printed onto a target surface, whereby the particle positions are precisely retained at a resolution that is three orders of magnitude higher than in conventional printing.”

The printing template geometries explored include lines to produce closely-packed nanoparticle wires, which could be used in molecular electronics; regularly spaced arrays of gold particles as seeds for nanowire growth; and arbitrary arrangements, such as the printed replica of the sun. The long-range accuracy, which measures the deviation from the desired arrangement on a large area, is similar to that of microcontact printing methods. The next steps will be to refine the method to achieve even higher accuracies, as would be required for large-scale integration in microelectronics, as well as to extend the method to print even smaller particles.

Source: IBM