Bend it like... a Millipede?

While industry spends billions bending and shaping sheets of metal, a team in this year's UQ Business School Enterprize competition claims that it can do it better – and cheaper.

While that may sound like the old "better mousetrap" scenario, the team's concept plan shows they have clearly identified a need for their product and hence a potential market.

Spokesperson Dr Paul Meehan said the team had come up with a new technique for manufacturing tubes and channels for a wide range of industrial and domestic applications including structural beams and corrugated iron.

“Our press former, Millipede, has several compelling benefits over existing machines,” he said.

“In prototype at least it significantly reduces defects in the finished product, uses energy more efficiently, lowers production costs, decreases set up times, and improves safety because our machine can be fully enclosed.

"It will extend the existing range of formed products in difficult areas the market is demanding now."

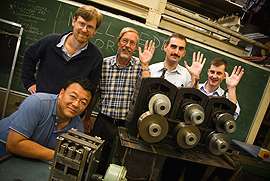

Dr Meehan said the idea had developed while he and team members Drs Scott Ding and Bill Daniel had struggled with several key limitations using existing technologies under an ARC Linkage grant with Smorgon Tube Mills.

“Thanks to our Manager of Innovation and Commercial Development Dr Howard Leemon, we were able to source funding very quickly to build a working small-scale prototype," he said.

“Interestingly, the prototype itself may turn out to be commercially viable at its small size as it makes it possible to manufacture very small diameter tubes and channels – something existing technology is unable to offer.

“The next step though will be to build a full scale prototype with a suitable partner.”

As for potential markets, Dr Meehan says the problem is trying to narrow it down to one or two areas to start with.

“The benefits of this technology will make many manufacturers want to replace their existing machines with the novel press former; however, initially using the Millipede to produce traditionally difficult products such as stainless steel tubes will demonstrate its potential," he said.

“Some companies might be able to bring some manufacturing in house because this machine will be so much smaller and easier to use and there may turn out to be a market for mobile novel press formers that can be used on site.

“And the rapid industrialisation of China and India opens up huge opportunities for an idea like this.”

A University of Queensland MBA student is currently researching potential markets as the team gets ready to pitch its idea to an audience of venture capitalists and investors on Thursday, October 11, at the UQ Business School Enterprize Pitch Day in Brisbane.

Source: UQ