July 26, 2007 feature

Simple Method Yields Complex Micro- and Nanoparticle Shapes

In applications from drug delivery to electronics, polymer particles several billionths to millionths of a meter in size could play key roles. But before many of these uses can be realized, scientists must thoroughly understand how these particles behave – behaviors that are strongly linked to the particles' precise shapes, which so far have been difficult to produce on demand and in variation. Recently, however, scientists from the University of California at Santa Barbara (UCSB) found a way to widen this bottleneck.

“There is a shortage of methods to produce non-spherically shaped polymer particles. We have developed a method that addresses this challenge,” said UCSB engineer Samir Mitragotri, the study's corresponding scientist, to PhysOrg.com.

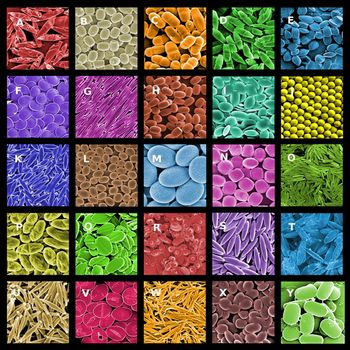

The method is fairly simple, low cost, and can produce substantial quantities of particles (from billions to trillions) of more than 20 widely varying shapes. These include rods, various disks, bullets, barrels, and lenses.

The particles are made of polystyrene, a polymer most commonly used to make foam packaging materials. The pre-shaped particles are spherical and have diameters between 60 nanometers (billionths of a meter) and 10 micrometers (millionths of a meter).

The particles are first suspended in a polymer solution, cast into films of varying thicknesses, and mixed with the compound glycerol to plasticize the films. The films were then dried. From there, the researchers used two approaches, dubbed A and B, and then a combination of the two, to engineer the full array of shapes.

In approach A, the particles were melted using either a solvent or heat and then the entire film was stretched on an apparatus custom built for the task. By stretching the film in one, two, or both directions, the particles were pulled into various shapes. Different shapes resulted from the use of solvent versus heat, and the thickness of the film also produced new geometries. Among the shapes yielded by approach A were circular disks, rectangular disks, “flying saucers,” rods, and worms.

In approach B, the films were stretched before melting, which produced a different set of shapes than A, most more complex, including pulley wheels, barrels, bullets, and capsules.

Combining approaches A and B resulted in yet another set of shapes, many rather unusual. These included ribbon-like particles with curled ends, elongated hexagonal disks, and even “ravioli” and “tacos.”

Most of the shapes produced were a few micrometers in size, but the scientists were able to produce nanoparticles, which greatly increases the particles' potential applications. The group says that particles made of polymers other than polystyrene could be produced using their method, and that the method is scalable to produce even greater numbers of them.

Added Mitragotri, “There is already evidence supporting the importance of particle shape in various applications, such as the design of new carriers for drug delivery. We believe that the availability of a simple method to make these particles will lead to many new discoveries and technologies.”

Citation: Julie A. Champion, Yogesh K. Katare, and Samir Mitragotri (2007) Proc Natl Acad Sci USA 104:11901-11904

Copyright 2007 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.