March 12, 2006 feature

Nano-scale fuel cells may be closer than we think, thanks to an inexpensive new manufacturing method

We live in a world of hand-held devices: iPods, cell phones, PDAs, pagers... the list of essential personal technology keeps expanding, and the natural response is consolidation. It’s rare these days to see a new cell phone that isn’t also a digital camera, and MP3 players can be integrated into just about anything. We’re just a short step away from universal, hand-held devices that combine communication, media, and entertainment into one slim package. What’s stopping us? In a word, power.

Cell phones last a few days on a single battery; laptop computers, two to three hours. If you could have a pocket-sized personal computer with a cell-phone sized battery, how long do you think it would last? Just long enough to check your e-mail, or play a game of solitaire? It’s a sad but unavoidable fact that the more complicated an electronic device gets, the less efficient it is.

Enter fuel cells, with an energy capacity at least ten times greater than that of conventional batteries. Where a lithium-ion battery can provide 300 Watt-hours per liter, the methanol in a fuel cell has a theoretical capacity of up to 4800 Watt-hours per liter! Imagine your laptop running for a full day without needing to recharge, and you can see why industry leaders such as Toshiba, IBM, and NEC have been pouring funds into fuel cell research.

A polymer-electrolyte membrane (PEM) fuel cell generates current by stripping hydrogen atoms from a chemical source, breaking them apart on a catalyst (such as platinum), and harvesting the electrons. The hydrogen ions (protons) left over from this process are separated from the fuel by an electrolyte, and when brought into contact with the atmosphere they bind to oxygen molecules and produce water. The more fuel you can bring into contact with the catalyst, the more current can be drawn from the cell. A high catalytic surface area is the key to efficiency.

To compress more power into smaller volumes, researchers have begun to build fuel cells on the fuzzy frontier of nanotechnology. Silicon etching, evaporation, and other processes borrowed from chip manufacturers have been used to create tightly packed channel arrays to guide the flow of fuel through the cell. The point is to pack a large catalytic surface area into a wafer-thin volume. This approach is not only expensive, but inherently limited by its two-dimensional nature.

Fiat Lux!

Researchers Kenneth Lux and Karien Rodriguez, at the University of Wisconson, came up with an exciting new approach to the problem. Their method not only improves the performance of nano-scale fuel cells, but completely sidesteps the need for industrial-strength technology. “Even the best electrocatalysts, on a flat surface, give only hundreds of microamps per square centimeter. What you really want is … to increase the surface area by orders of magnitude.” Lux explains to PhysOrg.com, “To do this you need a three-dimensional structure.”

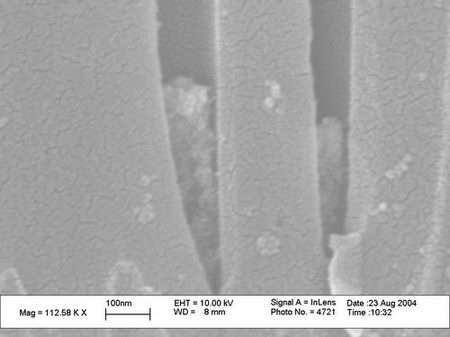

Lux and Rodriguez found their fuel channels ready-made in a commonly available, porous alumina filter costing only about $1. The filter is riddled with neat, cylindrical holes only 200 nanometers in diameter, and was already being used at their lab as a template for the growth of nanowires. Lux hit on the idea of creating nanowires in a platinum-copper alloy, then dissolving the copper by soaking the filter in nitric acid. In place of a solid nanowire, each hole was left with a porous platinum electrode. The partially dissolved wires are structurally complex, as befits their random nature, and have an enormous surface area for their size.

To build a fuel cell, they fill the pores with acid. A sheet of electrolyte-loaded filter paper (or polymer-electrolyte) is placed between two of the nano-electrode arrays to carry off the hydrogen ions. Electrodes can then be placed anywhere on the outer surface of the sandwich, allowing the electrical connections to be easily configured. Stacks of these fuel cell arrays can be connected in series or parallel, to provide higher voltage or current respectively.

Of course, the result is hardly perfect. Lux estimates that only a third of the electrodes are active, and admits that there is a lot of room for improvement. Even this proof-of-concept prototype, however, has an energy capacity an order of magnitude higher than its two-dimensional lithographic counterparts! The price can’t be beat, either, with a total materials cost of only $200. “It’s a really simple method.” says Lux, “My power source [for making the nanowires] was a AA battery.”

If fuel-cell technology can be perfected, we might be looking at a future of cheap, disposable battery packs for our favorite electronic gadgets. When your universal media manager runs out of energy, you'll just run to the store and buy it a methanol sandwich!

Citation: Template Synthesis of Arrays of Nano Fuel Cells, Kenneth W. Lux and Karien Rodriguez, Nano Letters 6, 2006

by Ben Mathiesen, Copyright 2006 PhysOrg.com